1-800-868-2450

My Account | Cart | Checkout

2025 Top Industrial Air Compressors: Key Features and Buying Guide

In the rapidly evolving landscape of industrial operations, air compressors play an indispensable role in driving efficiency and productivity. As we look toward 2025, it becomes essential to understand the key features and criteria for selecting the best air compressor industrial products for various applications. According to John Smith, a renowned expert in industrial air systems, "Investing in the right air compressor can significantly enhance operational performance and reduce long-term costs." This statement underscores the importance of making informed choices in the selection process.

Evaluating the specific needs of your operations is crucial in navigating the many options available in the market. Features such as energy efficiency, maintenance requirements, and noise levels can greatly influence your decision. As industries continue to prioritize sustainability and cost-effectiveness, understanding these facets of air compressor industrial technology will be vital for future-proofing your business. With the right knowledge and insights, stakeholders can confidently select equipment that not only meets their current demands but also accommodates future growth.

Key Features to Look for in Industrial Air Compressors

When considering industrial air compressors, several key features play a crucial role in ensuring optimal performance and efficiency for your operations. One of the primary aspects to evaluate is the compressor type. Depending on your specific needs, you may prefer

rotary screw compressors for continuous operation or

reciprocating compressors for occasional use. Each type has unique advantages, which can affect productivity and maintenance costs, so it's essential to select the one that aligns with your application requirements.

Another important feature to focus on is the airflow volume and pressure ratings. Assessing the demands of your tools and machinery will help you determine the necessary CFM (cubic feet per minute) and PSI (pounds per square inch) ratings, ensuring that the compressor can support your operational needs without overloading. Additionally, energy efficiency should not be overlooked, as industrial air compressors can significantly impact your energy consumption. Look for models that offer advanced technology for improved efficiency, as this will not only lower operational costs but also reduce your environmental footprint.

Durability and maintenance requirements are also critical considerations. Compressors made from high-quality materials are more likely to withstand harsh working conditions and have a longer service life. Regular maintenance features, such as easy access to filters and oil ports, can facilitate routine checks and minimize downtime, making these aspects vital for maintaining a productive workflow.

Types of Industrial Air Compressors and Their Applications

When it comes to industrial air compressors, understanding the various types and their specific applications is crucial for optimizing operations. There are generally three main categories of industrial air compressors: reciprocating, rotary screw, and centrifugal. Each type serves distinct purposes based on the required pressure and airflow. According to a recent market report by Grand View Research, the global industrial air compressor market size was valued at approximately $34 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 4.4% from 2023 to 2030. This growth underscores the importance of choosing the right type of compressor for the intended application.

Reciprocating compressors are favored for their ability to deliver high-pressure output, making them ideal for industries such as automotive and manufacturing, where precise control is required. On the other hand, rotary screw compressors are more efficient for continuous operations and provide a steady airflow, often used in food processing and chemical applications. Centrifugal compressors, while less common, are utilized in large-scale operations requiring high volumes of compressed air, such as power generation and large HVAC systems. The selection of the right compressor type can significantly enhance energy efficiency and operational reliability, which are critical factors, especially considering that energy costs can account for up to 70% of the lifetime operating expenses of an air compressor.

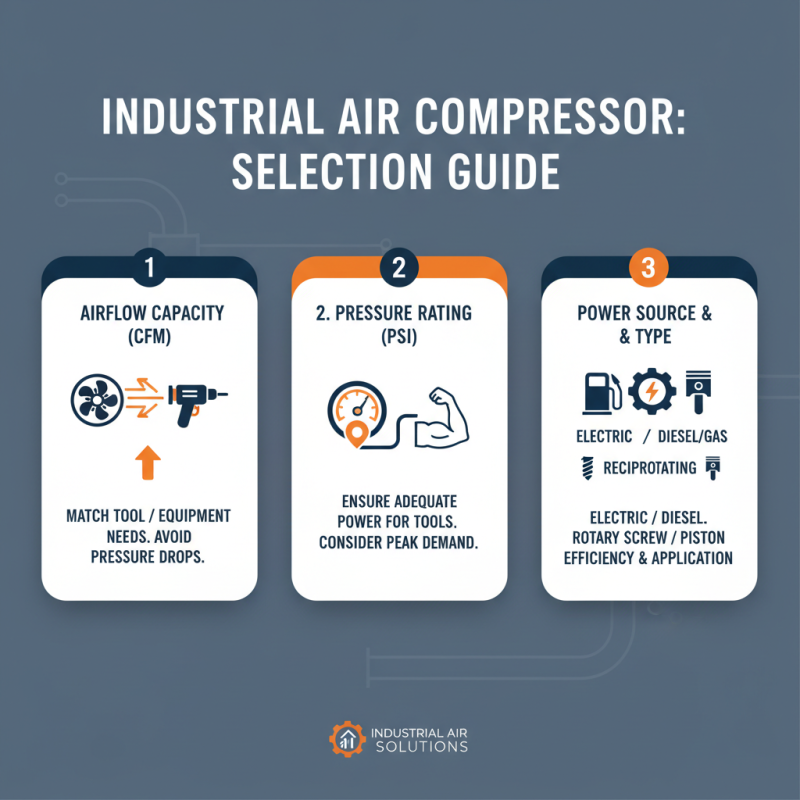

Buying Guide: Factors to Consider When Choosing an Air Compressor

When choosing an industrial air compressor, there are several critical factors to consider to ensure that the selected unit meets your operational needs effectively. Firstly, evaluate the compressor's airflow capacity, usually measured in cubic feet per minute (CFM). This measure reflects the amount of air the compressor can deliver and should be aligned with your applications to avoid scenarios where the unit cannot sustain the required pressure for tools or equipment.

Another important factor is the pressure output, often measured in pounds per square inch (PSI). Depending on your industrial applications, certain tasks may require higher or lower pressure levels. Additionally, consider the compressor's energy efficiency, as this will impact your overall operational costs. Look for models that can efficiently convert power into compressed air with minimal waste. Maintenance needs, portability, and noise levels are also key considerations that can affect the ease of use and overall productivity in your workspace. These features combined will help you select an air compressor that not only meets your requirements but also enhances the efficiency of your operations.

Maintenance Tips for Maximizing Air Compressor Lifespan

Proper maintenance is crucial for maximizing the lifespan of your industrial air compressor. Regular inspections can help identify potential issues before they become significant problems. Ensure that you frequently check the oil levels and replace it according to the manufacturer's recommendations. Additionally, keep an eye on the air filters; dirty filters can restrict airflow and lead to increased wear on the compressor components.

One of the best maintenance tips is to maintain clean surroundings. Dust and debris can infiltrate the compressor and hinder its performance. Regularly clean the area around your compressor and ensure that it is free from obstructions. Furthermore, establish a maintenance schedule that includes routine checks for leaks, belt wear, and overall system performance. Consistent attention to these details can significantly enhance your compressor's efficiency and lifespan.

Another important aspect is monitoring the temperature during operation. Overheating can lead to significant damage, so ensure that your unit is not running in excessively hot conditions. If necessary, consider investing in additional cooling solutions or fans to help manage heat. Following these maintenance tips will not only extend the life of your air compressor but also improve its operational efficiency.

Top Brands to Consider for Industrial Air Compressors in 2025

When it comes to choosing industrial air compressors in 2025, it's essential to understand the leading brands in the market. Companies that focus on innovation, durability, and efficiency have emerged as top contenders. Look for brands that not only provide high-quality compressors but also offer extensive customer support and warranty options. These factors can significantly affect the long-term performance and maintenance costs of your equipment.

Tips for selecting the right brand include assessing the manufacturer's reputation and customer reviews. Engaging with industry forums can also provide insights into which brands are regarded as reliable and which models have proven successful in various applications. Additionally, consider the range of products offered by a brand; a company with a diverse lineup may better meet specific needs, whether you're looking for portable solutions or stationary, heavy-duty compressors.

Another valuable tip is to evaluate the energy efficiency ratings of potential air compressors. Brands that prioritize sustainability and energy-saving technology can help lower operational costs while minimizing environmental impact. Don’t forget to inquire about the availability of spare parts and accessories, as this can enhance the ease of maintenance and ensure your compressor operates at peak efficiency for years to come.

2025 Top Industrial Air Compressors: Performance Metrics

Related Posts

-

Maximizing Efficiency: How Industrial Air Compressors Transform Manufacturing Processes

-

Why Pressure Gauges are Essential for Accurate Measurements in Various Industries

-

10 Essential Tips for Choosing the Right Industrial Compressor for Your Business

-

Unlocking the Power of High Pressure Air Compressors for Home and Industry

-

Top 10 Industrial Compressors of 2023: Performance, Efficiency, and Reliability Insights

-

2025 How to Improve Air Treatment for Better Indoor Air Quality

Copyright © 2025

I&M Industrials Inc.

10 Akron Drive

Greenville SC 29605

Phone: 864-277-2450

GSA Number – GS07F0379Y