1-800-868-2450

My Account | Cart | Checkout

Top 10 Air Compressor Repair Tips You Need to Know?

When it comes to air compressor repair, knowing the right techniques can save time and money. John Smith, a seasoned expert in the industry, once said, “Understanding the fundamentals of air compressor repair can extend the life of your equipment.” This highlights the importance of proper maintenance and repair strategies.

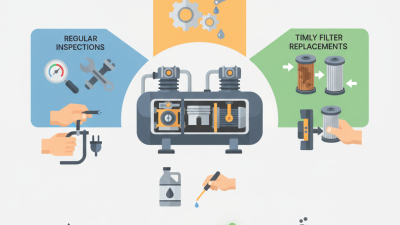

Regular inspections can prevent major breakdowns. Many users overlook simple signs of wear and tear. A small leak can lead to significant energy loss. Start by checking the hoses and fittings regularly. It’s crucial to stay proactive rather than reactive.

Furthermore, troubleshooting can be a daunting task. Not everyone possesses the technical skills required. It’s essential to educate yourself on common issues. Reading manuals and seeking expert advice can make a world of difference. Engaging in air compressor repair education is a wise investment.

Understanding Your Air Compressor: Common Problems and Solutions

Understanding your air compressor is crucial for effective maintenance.

Common problems often arise, such as air leaks.

These can occur at various points, including fittings or hoses. Regularly inspecting these areas can save time and money on repairs.

Identifying small issues early is key. A tiny leak can lead to significant efficiency loss over time.

Another frequent problem is the compressor not starting. This might stem from electrical issues or a clogged air filter.

Ensure to check the power supply before panicking. Sometimes, simply cleaning or replacing the filter can resolve the problem.

It is easy to overlook the basics when troubleshooting. Taking a moment to look closely can yield surprising results.

Lastly, operators may notice abnormal noises. Grinding or rattling sounds usually indicate mechanical issues.

They shouldn’t be ignored. These noises often hint at wear and tear or a need for lubrication. Regular maintenance is essential but sometimes neglected.

Taking time to reflect on these minor details can enhance the longevity of your compressor. Pay attention to the sounds it makes, and don’t dismiss your instincts.

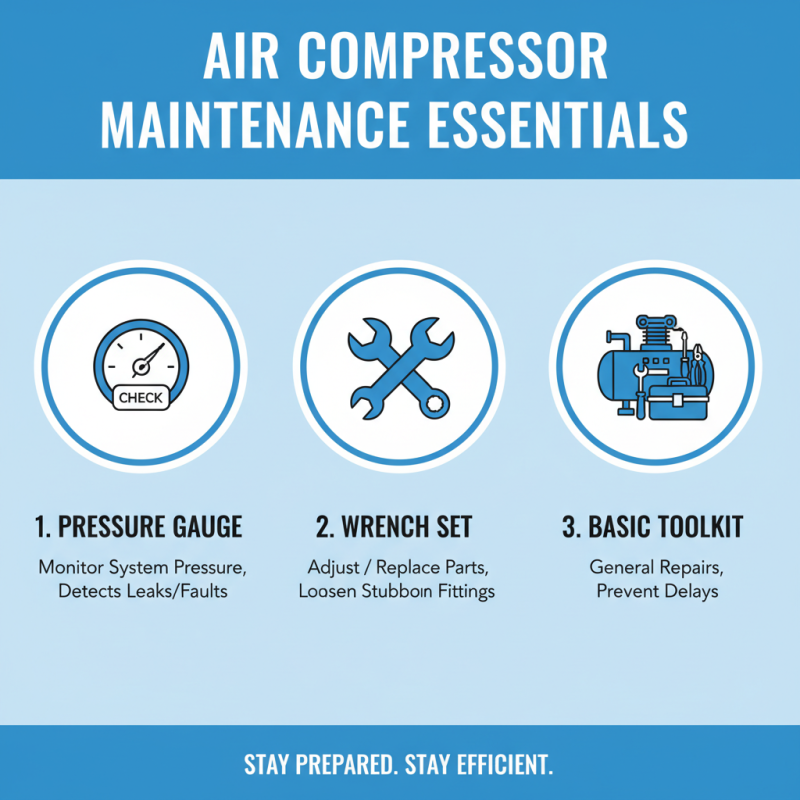

Essential Tools for Air Compressor Maintenance and Repair

When it comes to maintaining your air compressor, having the right tools is crucial. A quality pressure gauge is a must-have for checking the system pressure. This simple tool helps identify leaks or faults in the compressor's output. Moreover, a basic set of wrenches can make adjusting or replacing parts easier. Sometimes, a stubborn fitting can frustrate your repair attempts, leading to unnecessary delays.

In addition to wrenches and gauges, don’t forget about lubricants. Various moving parts benefit greatly from proper lubrication. Investing in good oil prevents wear and can extend the lifespan of your compressor. A vacuum pump is another valuable tool. It assists in removing moisture and air from the system, ensuring smooth operation. Despite these tools, issues can still arise. It's easy to overlook regular checks, which can lead to more significant problems down the line. Regularly inspecting hoses and connections can save a lot of headaches later.

Step-by-Step Guide to Diagnosing Air Compressor Issues

Diagnosing air compressor issues can seem daunting. A systematic approach helps in identifying problems. Start by checking the power supply. Ensure the compressor is plugged in and the circuit is functioning. This simple step often resolves power-related issues.

Listen for unusual sounds during operation. Grinding or clattering noises may indicate internal wear. These can signal a need for maintenance or replacement parts. Regularly inspect the air filter, too. A clogged filter restricts airflow and reduces efficiency. Clean or replace it as needed to keep your compressor running smoothly.

Additionally, monitor the pressure gauge. Fluctuating readings may point to leaks or improper settings. Inspect the hoses and connections for signs of wear. A small leak can lead to significant efficiency losses. Address these issues promptly to avoid more extensive repairs later. Taking these steps can enhance your air compressor's lifespan and effectiveness.

Top 10 Air Compressor Repair Tips You Need to Know

| Tip Number | Repair Tip | Description |

|---|---|---|

| 1 | Check the Power Supply | Ensure the compressor is plugged in and that the circuit breaker is not tripped. |

| 2 | Inspect the Air Filter | Clean or replace the air filter to prevent clogs and improve airflow. |

| 3 | Check for Leaks | Inspect hoses and fittings for leaks to ensure pressure is maintained. |

| 4 | Examine the Hoses | Check for cracks or damage to hoses; replace if necessary to prevent failures. |

| 5 | Maintain Oil Levels | Check and maintain proper oil levels for lubricated compressors. |

| 6 | Clean the Condenser Coils | Dust buildup on coils can affect efficiency; clean regularly. |

| 7 | Check the Pressure Switch | Ensure the pressure switch is functioning correctly for safe operation. |

| 8 | Inspect Safety Valves | Test safety valves periodically to ensure they release excess pressure. |

| 9 | Regularly Check the Drain Valve | Drain moisture from the tank regularly to prevent rust and corrosion. |

| 10 | Schedule Professional Maintenance | Consider professional check-ups to catch issues before they become serious. |

Preventive Measures: Extending the Life of Your Air Compressor

Air compressors are crucial for many industries. Regular maintenance can extend their lifespan significantly. A recent industry report highlighted that proper upkeep can increase efficiency by up to 30%. Neglecting routine checks leads to problems like overheating. Dust and debris accumulation can result in wear and tear.

Using quality filters is essential. They keep contaminants out, improving air quality and performance. A study revealed that replacing filters regularly can reduce downtime by 20%. Keeping the compressor clean is important too. Regular cleaning prevents corrosion and ensures smooth operation.

It's easy to overlook small issues. Listen for unusual noises or vibrations. Ignoring these signs can escalate repairs. Be proactive. Schedule maintenance checks at regular intervals. This lowers the chances of unexpected breakdowns. Remember, a little attention today saves big troubles tomorrow.

Top 10 Air Compressor Repair Tips

Best Practices for Safe Air Compressor Operation and Repair

When operating an air compressor, safety is paramount. Always wear protective gear such as goggles and gloves. These safeguards minimize the risk of accidents. Additionally, ensure your workspace is clean and free of clutter. It helps prevent unexpected injuries. Regularly inspect the compressor for leaks. Even a small leak can lead to bigger problems.

Proper maintenance is another key aspect. Check the oil levels frequently and replace it when needed. Dirty or low oil can cause performance issues. Also, clean or replace the air filter regularly. A clogged filter restricts airflow and can lead to overheating. Keep an eye on the pressure settings too. Incorrect pressure can damage equipment.

Lastly, be mindful of your operational techniques. Avoid overloading the compressor with excessive work. It puts unnecessary strain on the machine. Ultimately, understanding these practices helps extend the life of your air compressor. A well-maintained unit is safer and more efficient. Do not overlook simple tasks that can prevent major failures. Regular reflection on these practices is essential for safe and effective operation.

Related Posts

-

How to Effectively Maintain Your Air Compressor for Optimal Performance

-

What is Compressor Maintenance and Why is it Important?

-

2025 Top Industrial Air Compressors: Key Features and Buying Guide

-

Top 10 Benefits of Using an Oil Free Compressor for Your Projects

-

Unlocking the Power of High Pressure Air Compressors for Home and Industry

-

Why Pressure Gauges are Essential for Accurate Measurements in Various Industries

Copyright © 2025

I&M Industrials Inc.

10 Akron Drive

Greenville SC 29605

Phone: 864-277-2450

GSA Number – GS07F0379Y