1-800-868-2450

My Account | Cart | Checkout

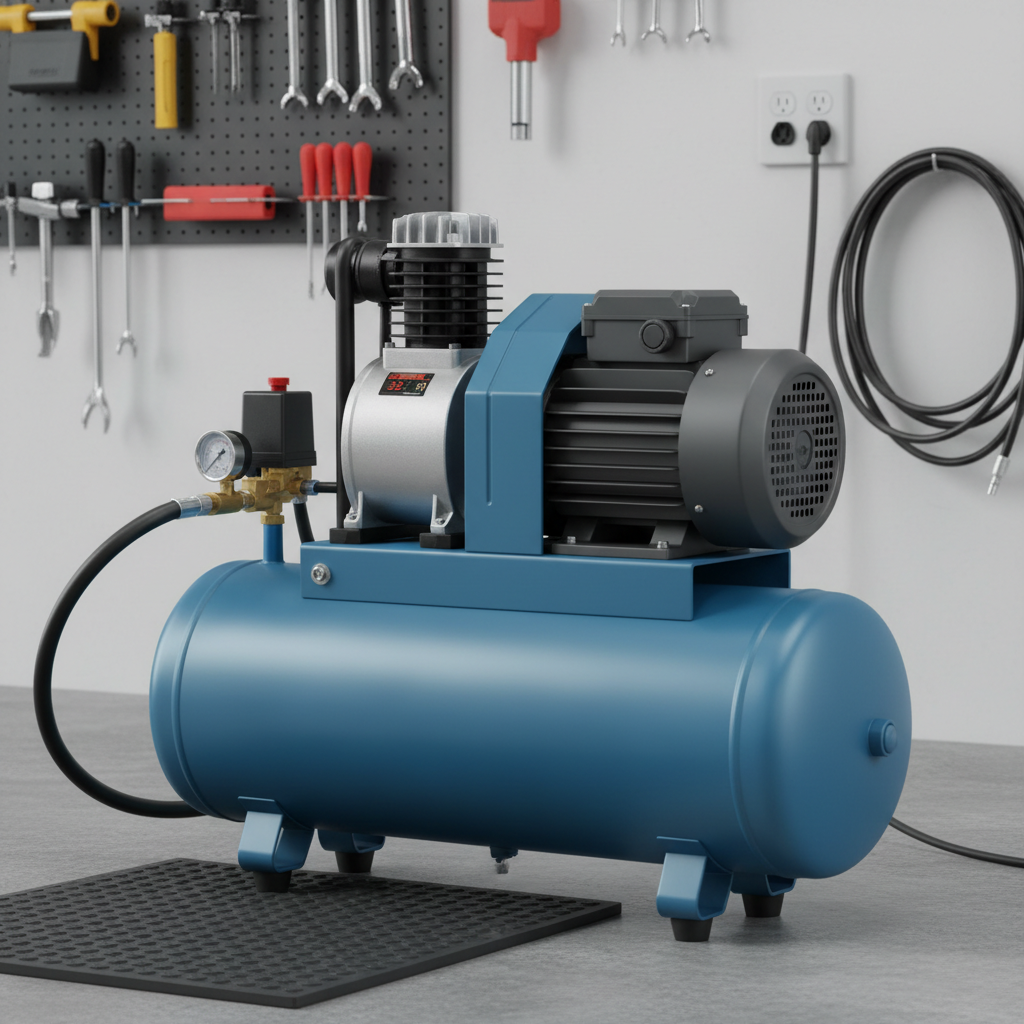

Top 10 Air Compressor Models for Efficient Performance and Reliability in 2023

In the ever-evolving landscape of power tools and equipment, air compressors play a vital role in both professional and DIY applications. As we step into 2023, the demand for efficient, reliable, and high-performance air compressor models continues to rise, driven by advancements in technology and increased user expectations. With a plethora of options available in the market, selecting the right air compressor can be daunting. Our comprehensive guide, "Top 10 Air Compressor Models for Efficient Performance and Reliability in 2023," aims to simplify this selection process, offering insights into the best-performing models categorized by their unique features and applications.

This carefully curated list focuses not only on the efficiency of each air compressor but also on their overall reliability in various working conditions. Whether you're seeking an air compressor for heavy-duty industrial tasks, home improvement projects, or even hobbyist pursuits, understanding the key specifications and performance metrics is crucial. Join us as we delve into the top contenders for 2023, highlighting the characteristics that make these air compressors stand out in a competitive market, ensuring that you make an informed decision for your specific needs.

Top Features to Consider When Choosing an Air Compressor for 2023 Efficiency

When selecting an air compressor for efficiency in 2023, consider several key features that significantly impact performance and reliability. The first is the compressor type, with options including reciprocating, rotary screw, and scroll compressors. According to a report by the Air Compressor Market Analysis, rotary screw compressors are increasingly favored for industrial uses due to their ability to provide continuous air flow and greater energy efficiency, demonstrating a 25% improvement in power consumption compared to traditional reciprocating models.

Another critical feature to evaluate is the compressor's tank size and pressure rating. A larger tank offers the advantage of longer run times and reduced duty cycles, which can enhance energy efficiency. Industry data reveals that models with a 60-gallon tank can lead to a decrease in energy costs by up to 15% over time, as they require less frequent cycling. Additionally, look for compressors with higher PSI ratings, as they can handle a wider range of applications and tool requirements, providing versatility and reliability for various tasks throughout the year.

Evaluating Power and Noise Levels: Key Specifications for Optimal Performance

When selecting an air compressor for efficient performance in 2023, evaluating power and noise levels plays a crucial role in ensuring optimal operation. According to the 2023 Air Compressor Market Report by ResearchAndMarkets, models equipped with motors ranging from 1.5 to 5 HP offer a balance between energy efficiency and power output, allowing users to tackle a variety of tasks without excessive energy consumption.

Moreover, carefully assessing the compressor's CFM (Cubic Feet per Minute) ratings reveals its capability to sustain airflow for pneumatic tools, where a range of 3 to 8 CFM is generally recommended for most applications.

Noise levels are another critical specification that significantly affects user experience. The industry's shift towards quieter models is evident; many manufacturers now produce units that operate below 70 dBA, as noted in a report from TechSci Research. This noise reduction contributes not only to a more pleasant working environment but also to compliance with local regulations regarding occupational noise exposure. Therefore, investing in air compressors that combine moderate power with low noise emissions not only enhances performance but also promotes a more sustainable workplace atmosphere.

The Importance of Tank Size and CFM Ratings in Air Compressor Models

When selecting an air compressor, understanding the importance of tank size and CFM (Cubic Feet per Minute) ratings is crucial for achieving efficient performance and reliability. The tank size directly impacts how long the compressor can operate before needing to refill. A larger tank can sustain air pressure longer, which is beneficial for tasks like spray painting or powering tools that require a continuous airflow. Conversely, smaller tanks are more portable and suitable for lighter, short-duration tasks.

CFM ratings indicate the volume of air a compressor can deliver at a set pressure level. Higher CFM ratings allow for more powerful tools to operate simultaneously, making it essential to match the compressor's CFM output with the requirements of the tools you'll be using. Therefore, when selecting a model, ensure it meets not just the peak demands but also fits your average usage.

**Tips:** Always consider your specific needs when choosing the tank size. If your tasks vary greatly, opt for a compromise in tank size that offers both portability and capacity. Additionally, check the CFM ratings of all tools that will be used with the compressor to avoid performance issues. Regular maintenance and understanding these specifications can greatly enhance the reliability and efficiency of your air compressor.

Top 10 Air Compressor Models: CFM Ratings vs Tank Size

Comparing Portability and Design: Which Air Compressor Suits Your Needs?

When selecting the right air compressor, portability and design should be at the forefront of your decision-making process. Depending on your specific needs, the weight and dimensions of the air compressor can significantly impact your efficiency. For those who require mobility, models with handles and wheels are ideal for easy transport across job sites. Lightweight, compact designs are perfect for DIY enthusiasts or professionals who need to move their equipment frequently, ensuring that they can work wherever their projects take them.

On the other hand, if you're operating in a stationary setup, a larger air compressor may offer superior power and efficiency. These models often come with enhanced features that optimize performance, making them suitable for demanding tasks such as spray painting or powering larger pneumatic tools. However, the design's aesthetics and functionality should not be overlooked; a machine that fits seamlessly into your workspace while providing reliability is essential.

Ultimately, whether you prioritize portability or design will depend on your unique requirements, making it crucial to carefully evaluate both aspects before making a decision.

Understanding Maintenance Requirements for Long-Term Reliability in Air Compressors

Proper maintenance is crucial for ensuring long-term reliability in air compressors. Regular inspection and servicing can prevent unexpected breakdowns, which not only boosts performance but also extends the life of the equipment. Key maintenance practices include checking the air filters, oil levels, and belts, as neglecting these elements can lead to decreased efficiency and increased energy costs. Additionally, it's important to regularly drain moisture from the tank, as accumulated water can cause corrosion and decrease the quality of the compressed air.

Another essential aspect of maintenance is monitoring the operating environment of the air compressor. High temperatures and dust can contribute to faster wear and tear, so placing the compressor in a clean, cool area is advisable. Furthermore, maintaining proper lubrication is essential, as it reduces friction and wear on moving parts, ensuring smoother operation. By adhering to a comprehensive maintenance schedule, users can significantly enhance the performance and reliability of their air compressors, ultimately leading to a more efficient operation in various applications.

Top 10 Air Compressor Models for Efficient Performance and Reliability in 2023

| Model | Power (HP) | Tank Size (Gallons) | Max PSI | Noise Level (dB) | Weight (lbs) | Maintenance Frequency |

|---|---|---|---|---|---|---|

| Model A | 3 HP | 60 Gal | 150 PSI | 75 dB | 200 lbs | Every 6 months |

| Model B | 5 HP | 80 Gal | 175 PSI | 70 dB | 250 lbs | Every 6 months |

| Model C | 2 HP | 30 Gal | 125 PSI | 76 dB | 100 lbs | Every 3 months |

| Model D | 4 HP | 50 Gal | 130 PSI | 72 dB | 180 lbs | Every 6 months |

| Model E | 6 HP | 100 Gal | 200 PSI | 68 dB | 300 lbs | Every 6 months |

| Model F | 3.5 HP | 40 Gal | 150 PSI | 74 dB | 150 lbs | Every 3 months |

| Model G | 2.5 HP | 20 Gal | 120 PSI | 80 dB | 90 lbs | Every 6 months |

| Model H | 1.5 HP | 15 Gal | 90 PSI | 88 dB | 70 lbs | Every 12 months |

| Model I | 5 HP | 60 Gal | 160 PSI | 73 dB | 210 lbs | Every 6 months |

| Model J | 4 HP | 75 Gal | 140 PSI | 71 dB | 230 lbs | Every 6 months |

Related Posts

-

Maximizing Efficiency: How Industrial Air Compressors Transform Manufacturing Processes

-

Top 5 Compressed Air Solutions to Boost Your Business Efficiency

-

10 Essential Tips for Choosing the Right Industrial Compressor for Your Business

-

How to Easily Find Affordable Compressor Repair Services in 2025

-

Top 10 Industrial Air Solutions to Optimize Your Facility's Efficiency

-

Maximizing Efficiency with Industrial Air Compressor Rental Services for Your Business Needs

Copyright © 2025

I&M Industrials Inc.

10 Akron Drive

Greenville SC 29605

Phone: 864-277-2450

GSA Number – GS07F0379Y