1-800-868-2450

My Account | Cart | Checkout

Top 10 Compressor Maintenance Tips You Can't Afford to Ignore

Effective compressor maintenance is crucial for ensuring the longevity and efficiency of your equipment. With industrial compressors playing a pivotal role in various applications, from manufacturing to HVAC systems, understanding how to maintain them properly can save time and prevent costly repairs. Neglecting regular maintenance tasks can lead to decreased performance, increased energy consumption, and potential breakdowns that could disrupt operations.

In this guide, we will explore the top 10 compressor maintenance tips that every operator should implement to safeguard their investment. From routine inspections to addressing common issues, these essential practices are designed to enhance operational reliability and extend the lifespan of your compressor. By prioritizing compressor maintenance, you can not only avoid unexpected downtime but also optimize productivity and reduce operating costs. Let's dive into these vital tips for maintaining your compressor effectively and efficiently.

Understanding the Importance of Compressor Maintenance

Compressor maintenance is a crucial aspect of ensuring optimal performance and longevity of your equipment. Regular maintenance not only prevents unexpected failures but also enhances efficiency, which can lead to significant cost savings in the long run. When compressors are neglected, they can experience wear and tear that could compromise their functionality, leading to costly repairs or replacements. Managers and operators must recognize that a proactive maintenance strategy is vital to avoid these operational disruptions.

Understanding the importance of compressor maintenance involves recognizing the key components that require regular attention, such as filters, belts, and lubricants. Maintaining clean filters can improve air quality and efficiency, while properly adjusted belts can reduce strain on the motor. Additionally, regular checks of lubrication levels and quality can prevent overheating and excessive wear. By prioritizing these maintenance tasks, organizations can extend the life of their compressors, maintain compliance with safety standards, and ensure uninterrupted operations.

Common Signs of Compressor Wear That Require Immediate Attention

Compressor systems are vital for numerous industrial applications, and recognizing the signs of wear can help prevent catastrophic failures. One common indicator is unusual noises, such as grinding, hissing, or rattling. These sounds often signal internal problems that require immediate inspection. Additionally, irregular vibrations during operation can indicate misalignment or mechanical wear, which can lead to further damage if not addressed promptly.

Another red flag is a noticeable increase in temperature. If a compressor is running hotter than usual, it could be a sign of insufficient lubrication or a failing component. This excessive heat can lead to premature wear and might compromise the integrity of seals and gaskets. Also, frequent trips to reset the protective devices or control system can indicate underlying issues, suggesting that the compressor is struggling to maintain its efficiency. Paying attention to these signs can lead to timely maintenance and extend the lifespan of your compressor.

Top 10 Compressor Maintenance Tips You Can't Afford to Ignore

| Tip | Frequency | Signs of Wear | Recommended Action |

|---|---|---|---|

| Check Oil Levels | Weekly | Low oil level warning | Top up or change oil |

| Inspect Air Filters | Monthly | Restricted airflow | Clean or replace filters |

| Tighten Connections | Quarterly | Vibrations, unusual sounds | Check and secure connections |

| Monitor Temperature | Daily | Overheating | Reduce load or check coolant levels |

| Regular Vibration Checks | Monthly | Excessive vibrations | Investigate and rectify root causes |

| Clean Condenser Coils | Bi-Annually | Poor cooling efficiency | Clean or replace as needed |

| Check Safety Valves | Annually | Pressure irregularities | Test and replace if malfunctioning |

| Inspect Electrical Connections | Quarterly | Burning smell, tripped breakers | Immediate repair or replacement |

| Schedule Professional Inspections | Yearly | Increased breakdowns or inefficiency | Follow expert recommendations |

| Document Maintenance Activities | Ongoing | Inconsistent maintenance records | Keep detailed logs for reference |

Step-by-Step Guide to Regular Compressor Maintenance Checks

Regular maintenance of compressors is essential for prolonging their lifespan and ensuring optimal performance. According to industry reports, nearly 70% of compressor failures can be attributed to inadequate maintenance practices. A systematic approach to compressor inspections can significantly reduce downtime and maintenance costs, ultimately leading to improved operational efficiency. Start by implementing a step-by-step checklist that includes evaluating oil levels, checking air filters, and ensuring proper lubrication. Research has indicated that regular lubrication can decrease component wear by up to 50%, making it a critical part of any maintenance routine.

Another crucial aspect of compressor maintenance is monitoring performance parameters. Routine checks of discharge pressure, temperature, and vibration levels can help detect early signs of problems. In fact, predictive maintenance practices, utilizing data analytics, can decrease repair costs by 25% and reduce equipment downtime by up to 40%. By adopting a structured maintenance schedule that includes regular performance assessments and timely interventions, facilities can ensure that their compressors operate at peak efficiency, thereby enhancing the overall productivity of their operations. Regular maintenance not only safeguards your investment but also contributes to a more sustainable and efficient business model.

Essential Tools and Supplies for Effective Compressor Care

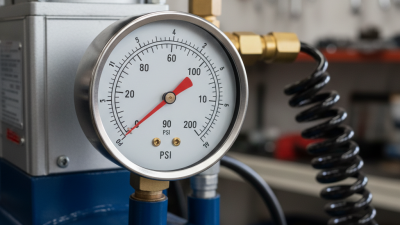

When it comes to effective compressor care, having the right tools and supplies is paramount for ensuring optimal performance and longevity. According to a report by the International Compressors Association, routine maintenance can extend the lifespan of compressors by up to 20%, significantly reducing overall operational costs. Key tools such as pressure gauges, oil analyzers, and thermometers are essential for monitoring compressor health, allowing technicians to identify issues before they escalate.

In addition to standard tools, incorporating specialized supplies can enhance the maintenance process. For instance, high-quality lubricants are vital for reducing friction and wear, ultimately improving efficiency. A study from the Journal of Mechanical Maintenance highlights that compressors with adequate lubrication run 15% cooler and experience 30% less wear on internal components. Furthermore, having essential safety gear, such as gloves and eye protection, is critical for maintaining a safe working environment while handling various compressor components.

Investing in these essential tools and supplies not only helps in maintaining the equipment's efficiency and reliability but also contributes to a safer and more productive workplace. Ensuring that your maintenance team is well-equipped is a proactive step in minimizing breakdown risks and maximizing operational uptime.

Top 10 Compressor Maintenance Tips You Can't Afford to Ignore

Best Practices for Storing and Handling Compressor Equipment

Proper storage and handling of compressor equipment are crucial for ensuring longevity and optimal performance. First and foremost, compressors should be stored in a clean, dry environment away from direct sunlight and extreme temperatures. This not only helps prevent corrosion but also shields delicate components from environmental damage. It's advisable to keep the compressor elevated from the ground to avoid water accumulation and potential rusting. Additionally, maintaining a consistent temperature can prevent the formation of condensation inside the unit, which can lead to serious mechanical issues.

When it comes to handling compressor equipment, caution is key. Always use the appropriate lifting equipment and techniques to avoid strain or injury, as compressors can be heavy and awkward to maneuver. Before moving a compressor, ensure it is completely turned off and depressurized to minimize risks. Furthermore, familiarize yourself with the equipment's manuals and safety guidelines to understand any specific handling needs. Regular inspections during storage are essential; checking for leaks and ensuring components are securely fastened can prevent malfunctions when the equipment is put back into operation.

Related Posts

-

Why Process Equipment is Essential for Efficient Industrial Operations

-

10 Essential Tips for Accurately Reading Your Air Compressor Gauge

-

Maximize Efficiency: The Surge in Industrial Air Compressor Rental Demand for Sustainable Practices in Manufacturing

-

Unlocking the Power of High Pressure Air Compressors for Home and Industry

-

Why Pressure Gauges are Essential for Accurate Measurements in Various Industries

-

Top 10 Air Compressor Models for Efficient Performance and Reliability in 2023

Copyright © 2025

I&M Industrials Inc.

10 Akron Drive

Greenville SC 29605

Phone: 864-277-2450

GSA Number – GS07F0379Y