1-800-868-2450

My Account | Cart | Checkout

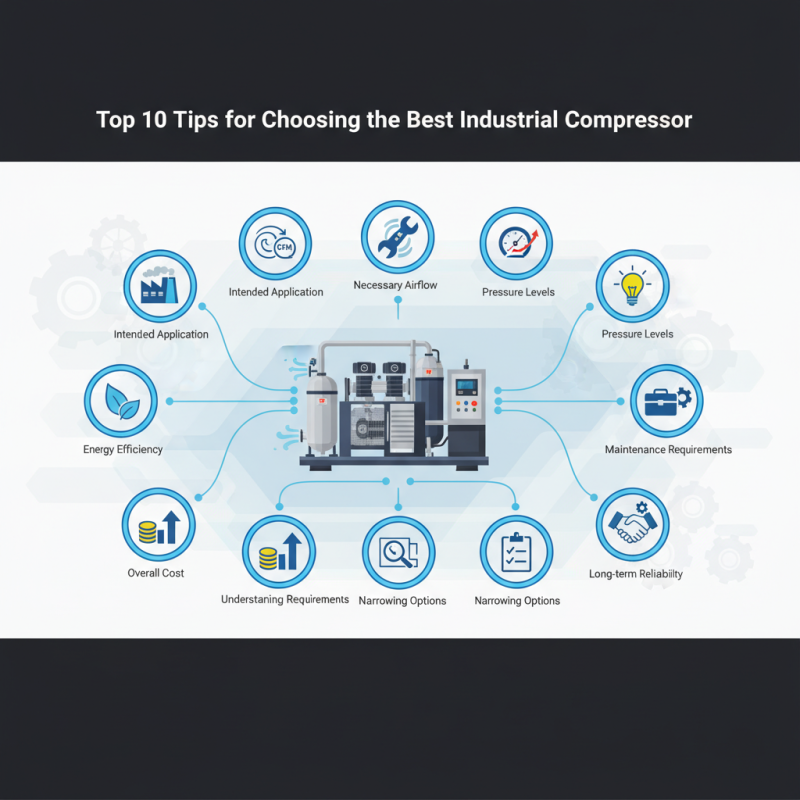

Top 10 Tips for Choosing the Best Industrial Compressor for Your Needs

Choosing the right industrial compressor is a critical decision that can significantly impact your operational efficiency and productivity. With a plethora of options available in the market, it can be overwhelming to determine which compressor best suits your specific needs. Industrial compressors vary in size, functionality, and application, making it essential to understand key factors that influence your choice. This guide aims to simplify the selection process by highlighting ten essential tips that can help you make an informed decision.

Understanding your requirements, such as the intended application, necessary airflow, and pressure levels, is the first step toward selecting the ideal industrial compressor. Whether you are involved in manufacturing, construction, or any other sector that relies on compressed air, grasping these fundamentals will enable you to narrow down your options effectively. Additionally, considerations involving energy efficiency, maintenance requirements, and overall cost will play a vital role in ensuring that your chosen compressor not only meets your operational demands but also aligns with your budgetary constraints. By following these tips, you can confidently select an industrial compressor that will serve your needs effectively for years to come.

Understanding Your Industrial Needs and Applications

When selecting an industrial compressor, understanding your specific operational needs and applications is crucial. Different industries have varying requirements based on the type of work being performed. For instance, according to the 2022 report by the Industrial Compression Association, the automotive sector often demands high-pressure air for pneumatic tools, while the food and beverage industry requires compressors with stringent hygienic standards to prevent contamination. This emphasizes the importance of defining the environment and conditions under which the compressor will operate.

Additionally, assessing the output requirements is vital. A report from the Global Industrial Compressor Market Research indicates that production capacities can range from as low as 1 CFM to over 1000 CFM, depending on the application. Understanding the specific demands of your processes, whether it's for spray painting, material handling, or refrigeration, will not only guide the selection of the right size and type of compressor but also ensure energy efficiency and reduce operational costs. Therefore, a thorough evaluation of your industrial needs helps to optimize performance and maintain productivity levels across your operations, ultimately resulting in a better return on investment.

Key Specifications to Consider When Choosing a Compressor

When choosing an industrial compressor, understanding key specifications is crucial for ensuring that you select the right equipment for your operational needs. According to a recent market analysis by Research and Markets, the global industrial compressor market is projected to grow at a CAGR of 3.7% between 2023 and 2028, emphasizing the importance of making informed decisions in a competitive landscape.

One of the primary specifications to consider is the compressor type, which can significantly impact efficiency and performance. Rotary screw compressors are favored in continuous operation settings due to their reliability and lower maintenance costs, while reciprocating compressors are ideal for intermittent use, offering versatility in pressure ranges. Additionally, assessing the required airflow capacity, typically measured in cubic feet per minute (CFM), is essential. A detailed study by Global Industry Analysts highlights that understanding the specific CFM requirements based on peak usage is crucial for avoiding undersized or oversized units, which can lead to inefficient energy consumption.

Another critical factor is the operating pressure, which influences the compressor's power consumption and overall productivity. Compressors typically operate between 100 to 175 PSI, but the specific applications can dictate the necessary pressure ratings. Furthermore, noise level and energy efficiency ratings should not be overlooked, as these aspects can significantly affect workplace comfort and operational costs. The latest energy efficiency regulations from the U.S. Department of Energy suggest that selecting equipment with higher efficiency can lead to cost savings of 20-30%, reinforcing the need for careful evaluation of compressor specifications prior to purchase.

Types of Industrial Compressors and Their Features

When selecting an industrial compressor, it's crucial to understand the various types available and their unique features. The two primary categories are positive displacement compressors and dynamic compressors. Positive displacement compressors, which include rotary screw and reciprocating models, work by trapping a fixed amount of air and then reducing its volume to increase pressure. This type is known for its durability and efficiency, making it suitable for heavy-duty applications that require a consistent air supply.

On the other hand, dynamic compressors, such as centrifugal compressors, utilize high-speed rotating components to impart velocity to the air, converting kinetic energy into pressure. These compressors are ideal for high-flow applications and are often employed in larger industrial settings due to their ability to handle vast volumes of air with lower energy consumption per unit of output. Understanding the specific requirements of your application, including pressure and volume demands, will guide you in choosing the appropriate type of industrial compressor for optimal performance and efficiency.

Evaluating Energy Efficiency and Operating Costs

When selecting the best industrial compressor for your needs, evaluating energy efficiency and operating costs is paramount. According to the U.S. Department of Energy, compressed air systems can consume up to 30% of a facility's total electricity usage. Therefore, choosing a compressor with high energy efficiency ratings can lead to significant savings over time. Models that adhere to the latest energy efficiency standards, such as those set by the Compressed Air and Gas Institute (CAGI), typically feature advanced technologies that reduce energy consumption while maintaining output performance.

Operating costs extend beyond initial purchase price, including maintenance, energy consumption, and potential downtime. Industry data suggests that energy costs alone can represent about 75% of the total lifecycle costs of an industrial compressor. Selecting a unit that not only offers lower kilowatt usage but also incorporates smart control systems can enhance operational efficiency, thereby reducing overall costs. Regular maintenance and upkeep are also essential in avoiding inefficiencies that can raise operating expenses significantly. By understanding the long-term implications of energy consumption and maintenance, businesses can make informed decisions that align with their operational budgets and sustainability goals, ultimately leading to improved profitability.

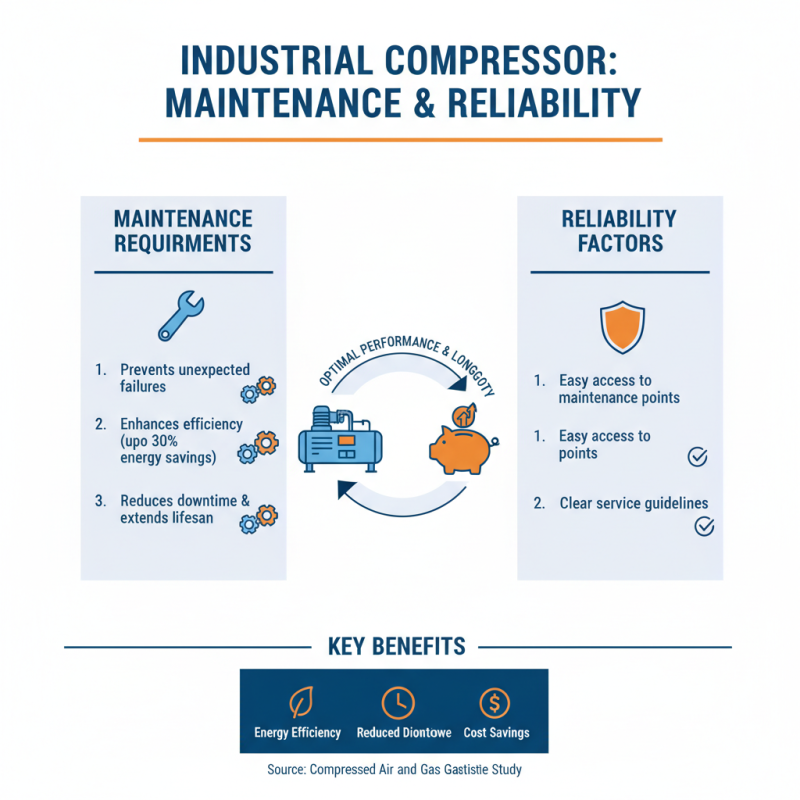

Maintenance Requirements and Reliability Factors in Compressors

When selecting the best industrial compressor, maintenance requirements and reliability factors play a crucial role in ensuring optimal performance and longevity. Regular maintenance not only prevents unexpected failures but also enhances the overall efficiency of the compressor. According to a study by the Compressed Air and Gas Institute, lack of proper maintenance can lead to up to a 30% increase in energy consumption, significantly impacting operational costs. Therefore, choosing a compressor with easy access to maintenance points and clear service guidelines can greatly reduce downtime and extend the lifespan of the equipment.

Another key aspect to consider is the reliability of the compressor, which is influenced by its design and components. A report by industry experts suggests that compressors built with high-quality materials and advanced engineering tend to have lower failure rates. When evaluating potential options, ensure to check for features such as integrated monitoring systems and proven durability ratings.

Incorporating a few essential tips can further guide your selection process. First, assess the manufacturer's service support and warranty offerings, as these can indicate the level of reliability you can expect from the compressor. Second, prioritize units that provide detailed maintenance schedules and easy-to-follow guidelines, facilitating proactive upkeep. Lastly, consider how the compressor's technology aligns with industry standards for energy efficiency, as this not only boosts reliability but also helps in reducing operational emissions.

Related Posts

-

Top 10 Industrial Compressors of 2023: Performance, Efficiency, and Reliability Insights

-

Unlocking the Power of High Pressure Air Compressors for Home and Industry

-

10 Essential Tips for Choosing the Right Industrial Compressor for Your Business

-

2025 How to Improve Air Treatment for Better Indoor Air Quality

-

How to Easily Find Affordable Compressor Repair Services in 2025

-

Top 10 Compressor Maintenance Tips You Can't Afford to Ignore

Copyright © 2025

I&M Industrials Inc.

10 Akron Drive

Greenville SC 29605

Phone: 864-277-2450

GSA Number – GS07F0379Y