1-800-868-2450

My Account | Cart | Checkout

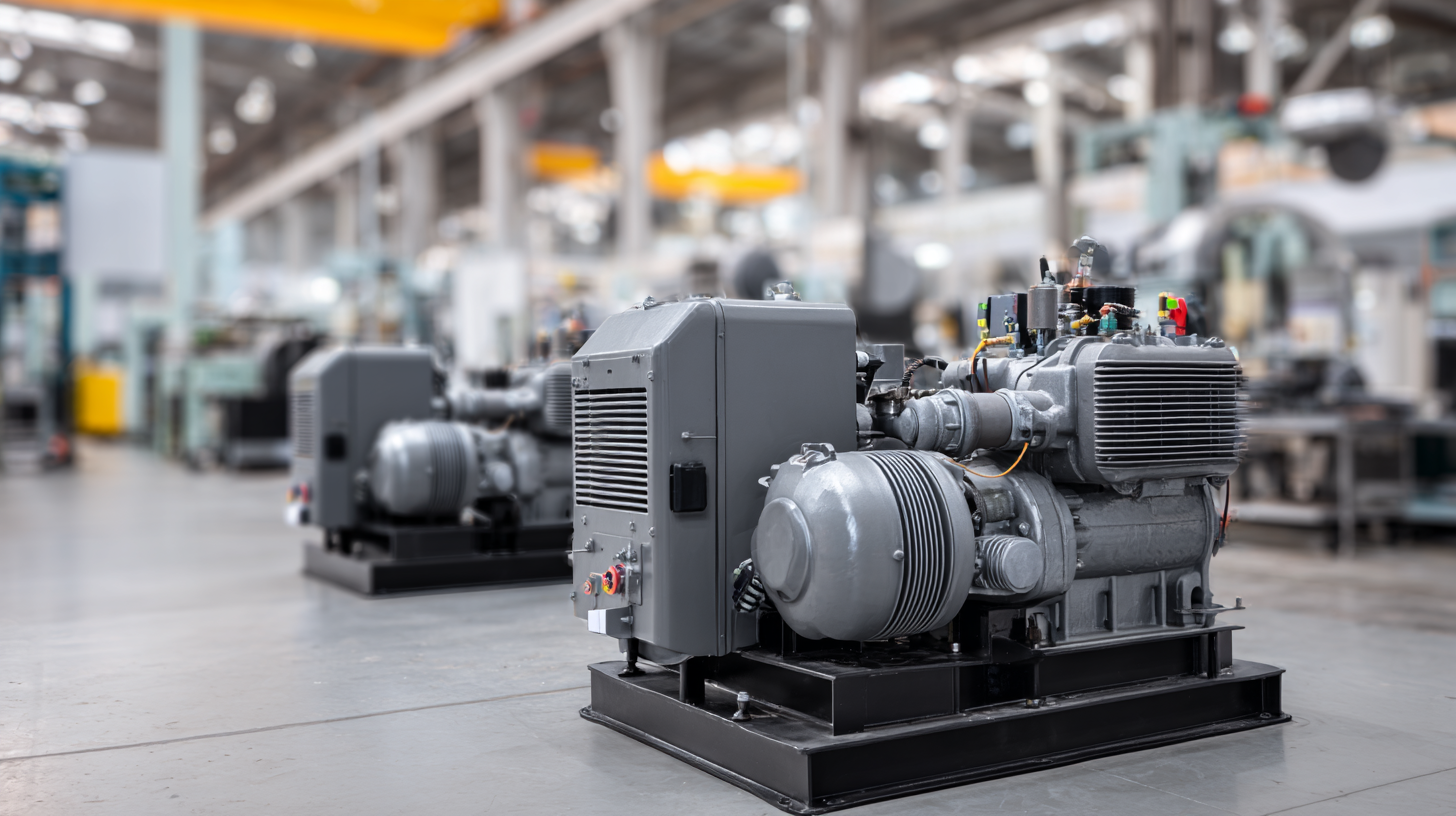

Maximizing Efficiency: How Industrial Air Compressors Transform Manufacturing Processes

In the competitive world of manufacturing, maximizing efficiency is paramount for success, and the role of the air compressor industrial cannot be understated. These powerful machines have revolutionized production processes across various sectors, enhancing operational productivity and reducing costs. By harnessing the power of compressed air, manufacturers can streamline workflows, optimize equipment performance, and offer higher quality products.

This article delves into the innovative ways air compressors are integrated into manufacturing, showcasing how they not only support basic functions but also drive technological advancements. From powering pneumatic tools to improving automation systems, the versatility of industrial air compressors is transforming how businesses operate, making them indispensable in the quest for efficiency.

As we explore the multifaceted benefits and applications of air compressor industrial, we will uncover practical approaches that manufacturers can adopt to leverage this technology for enhanced productivity.

The Role of Industrial Air Compressors in Streamlining Manufacturing Workflows

Industrial air compressors play a crucial role in streamlining manufacturing workflows by providing a reliable and consistent source of compressed air needed for various applications. They enhance the efficiency of machinery, enabling processes such as pneumatic conveying, powering tools, and operating production lines. By using air compressors, manufacturers can significantly reduce operational downtime, increase productivity, and maintain a steady output, which is essential in today’s competitive market.

**Tip**: Regular maintenance of your industrial air compressor is key to ensuring optimal performance. Schedule routine checks and replace filters to prevent inefficiencies and extend the life of the equipment.

Moreover, the integration of advanced technology in air compressors has allowed for greater control and automation in manufacturing processes. Smart compressors can adapt to fluctuating demands, ensuring that air supply is always matched to production needs, which helps in minimizing energy consumption and reducing operational costs.

**Tip**: Consider investing in variable speed drive (VSD) compressors to optimize energy efficiency. These compressors adjust their output according to the demand, providing significant savings in energy costs, especially in dynamic manufacturing environments.

Maximizing Efficiency: How Industrial Air Compressors Transform Manufacturing Processes

| Feature | Importance in Manufacturing | Impact on Efficiency | Cost Savings (%) |

|---|---|---|---|

| Energy Efficiency | Reduces energy consumption | Increases operational uptime | 15% |

| Automation Integration | Facilitates automated processes | Enhances production speed | 20% |

| Compact Design | Saves factory floor space | Improves workflow layouts | 10% |

| Low Maintenance | Decreases downtime | Optimizes worker productivity | 12% |

| Variable Speed Technology | Adapts to changing workload | Increases energy savings | 18% |

Key Technologies Enhancing Air Compressor Performance and Efficiency

Industrial air compressors play a pivotal role in modern manufacturing processes by enhancing productivity and efficiency. Key technologies driving the performance of air compressors include variable speed drives (VSDs), advanced filtration systems, and smart controls. VSDs allow compressors to adjust their speed according to demand, minimizing energy use and prolonging equipment life. Advanced filtration systems are essential for maintaining clean air, reducing downtime caused by maintenance issues, and increasing the overall reliability of the compressed air system.

Industrial air compressors play a pivotal role in modern manufacturing processes by enhancing productivity and efficiency. Key technologies driving the performance of air compressors include variable speed drives (VSDs), advanced filtration systems, and smart controls. VSDs allow compressors to adjust their speed according to demand, minimizing energy use and prolonging equipment life. Advanced filtration systems are essential for maintaining clean air, reducing downtime caused by maintenance issues, and increasing the overall reliability of the compressed air system.

Tip: Regularly inspecting and replacing filters can significantly improve the efficiency of your air compressor. Ensure you're monitoring pressure levels and adjust settings to meet specific operational needs.

Another emerging technology is the integration of IoT (Internet of Things) in air compressor systems, enabling real-time performance monitoring and predictive maintenance. This means that manufacturers can identify potential issues before they become critical, ultimately saving time and reducing costs associated with equipment failure.

Tip: Invest in IoT-enabled compressors to harness data analysis for improved maintenance schedules and to optimize operational efficiency. This proactive approach to managing air compressors can lead to better resource allocation and enhanced overall performance in manufacturing processes.

Cost-Benefit Analysis: The Financial Impact of Upgrading Air Compressor Systems

Upgrading air compressor systems can lead to significant cost savings and efficiency improvements in manufacturing processes. A comprehensive cost-benefit analysis reveals that modernizing to oil-free screw compressors not only enhances operational reliability but also reduces maintenance expenses and downtime. These systems eliminate the need for oil servicing, resulting in cleaner output and lowering the risk of contamination, particularly critical in industries like food and beverage where product purity is paramount.

Furthermore, the financial impact of deploying advanced compressor technologies can be substantial. While the initial investment might be higher, the long-term gains – including reduced energy consumption, lower operational costs, and extended equipment lifespan – often offset the initial expenditure within a few years. Industries that are adopting these upgrades are seeing improved productivity and reduced overheads, making a compelling case for manufacturing facilities to rethink their air compression solutions in favor of more efficient and sustainable options.

Real-World Case Studies: Air Compressors Driving Innovation in Manufacturing

In the manufacturing landscape, industrial air compressors are pivotal in enhancing operational efficiency. They serve as the backbone for various processes, from powering robotic arms to facilitating intricate packaging systems. This transformation is vividly illustrated through numerous real-world case studies showcasing how businesses have successfully implemented air compressors to innovate and streamline their workflows.

For instance, one factory reported a 25% decrease in production downtime after integrating a new high-efficiency air compressor system. This allowed them to boost output without incurring additional labor costs. Furthermore, the application of intelligent robotics in conjunction with these compressors has proven invaluable, especially in sectors like geriatric rehabilitation, where precision and reliability are paramount.

**Tip:** When considering the implementation of industrial air compressors, assess the specific needs of your operations to select the right model that balances efficiency with cost-effectiveness.

Additionally, understanding the maintenance requirements of these systems can prevent unexpected breakdowns. Regular servicing not only ensures optimal performance but can also extend the lifespan of the equipment, ultimately contributing to a more sustainable manufacturing process.

**Tip:** Keep a log of maintenance schedules and compressor performance metrics; this data can inform future upgrades and operational decisions.

Maximizing Efficiency: Air Compressors in Manufacturing

This chart illustrates the impact of industrial air compressors on manufacturing efficiency across various sectors. The data reflects the average efficiency gains in percentage before and after the implementation of air compressor systems.

Future Trends: The Evolution of Air Compressor Technology in Industry 4.0

The advent of Industry 4.0 has heralded a new era of efficiency and connectivity in manufacturing, with air compressor technology evolving to meet the demands of this transformative phase. In the quest for smart manufacturing, companies are increasingly integrating advanced air compressor systems equipped with IoT capabilities. These smart compressors can monitor performance in real-time, predict maintenance needs, and optimize energy consumption. This capability not only reduces downtimes but also enhances the overall productivity of manufacturing systems, allowing for precise control over the airflow and pressure required in various processes.

Looking ahead, we anticipate further advancements in air compressor technology driven by automation and artificial intelligence. Future models may incorporate machine learning algorithms that can learn from operational data, adapting their performance to changing workloads and environmental conditions. Additionally, sustainability will play a crucial role as manufacturers push towards greener practices, prompting the development of compressors that minimize energy waste and utilize eco-friendly refrigerants. As these innovations unfold, the role of air compressors will become even more critical, ensuring that manufacturing processes remain efficient, adaptive, and environmentally responsible in the rapidly evolving industrial landscape.

Copyright © 2025

I&M Industrials Inc.

10 Akron Drive

Greenville SC 29605

Phone: 864-277-2450

GSA Number – GS07F0379Y