1-800-868-2450

My Account | Cart | Checkout

Why Industrial Compressors are Essential for Efficient Manufacturing Processes

In today's fast-paced manufacturing landscape, the role of compressors industrial is increasingly vital for ensuring efficiency and productivity. The global industrial compressor market, valued at approximately $32 billion in 2022, is projected to grow at a CAGR of around 4.5% from 2023 to 2030, underscoring the indispensable nature of these machines in various sectors, including automotive, pharmaceuticals, and food processing. Compressors not only power critical operations but also contribute to energy savings, reliability, and process optimization, which are crucial in today's competitive environment.

Experts in the field, such as Dr. Emily Lewis, an authority on industrial systems, have emphasized the significance of efficient compression technologies. She stated, "The integration of advanced compressors industrial not only streamlines manufacturing processes but also reduces energy costs, pushing businesses towards a more sustainable future." This perspective highlights the dual benefits of efficiency and sustainability that modern compressors offer, making them an essential investment for manufacturers aiming to enhance their operational capabilities and environmental responsibility. As industries continue to evolve, the demand for high-performance compressors will only intensify, reinforcing their central role in the manufacturing process.

The Role of Industrial Compressors in Manufacturing Efficiency

Industrial compressors play a pivotal role in enhancing manufacturing efficiency across various sectors. By providing compressed air that powers machinery, tools, and systems, they help streamline operations and boost productivity. According to a report by MarketsandMarkets, the global air compressor market is projected to reach $41.9 billion by 2027, underscoring the critical demand for these devices in efficiency-driven environments. They facilitate processes such as material handling, spraying, and pneumatic conveying, all essential for maintaining a smooth production flow.

To maximize the efficiency of industrial compressors, manufacturers should consider implementing regular maintenance schedules and investing in energy-efficient models. For example, utilizing variable speed drive compressors can lead to energy savings of 20-50%, as noted by the Compressed Air and Gas Institute (CAGI). Furthermore, integrating compressor monitoring systems helps identify leaks and reduce waste, potentially saving companies thousands in operational costs.

**Tips:** Regularly analyzing your compressed air system can pinpoint inefficiencies and leaks that may go unnoticed. Additionally, scheduling compressor load tests can help ensure your equipment operates at optimal levels, further enhancing productivity in manufacturing processes.

Types of Industrial Compressors and Their Applications

Industrial compressors are critical components in various manufacturing processes, facilitating the efficient operation of machinery and systems. Among the different types of compressors, reciprocating compressors are widely utilized for their ability to generate high-pressure gases. The global market for reciprocating hydrogen compressors is anticipated to grow significantly, projected to reach $2.12 billion by 2032. This growth reflects the increasing demand for hydrogen as an energy source and its applications in diverse industries, including chemical processing and renewable energy.

Air compressors also play a pivotal role in the industrial landscape, with the global market expected to expand to $29.3 billion by 2032. This surge is primarily driven by rapid industrialization and automation, as businesses seek energy-efficient solutions to enhance productivity. Additionally, the natural gas compressor market is poised for growth, projected to hit $7.8 billion by 2034, driven by the rising demand for natural gas in power generation and transportation.

Overall, the various types of industrial compressors not only advance production efficiency but also support the transition toward more sustainable energy practices.

Key Benefits of Using Compressors in Production Processes

Industrial compressors play a pivotal role in modern manufacturing, driving efficiency and productivity. According to a report by MarketsandMarkets, the global industrial air compressor market is projected to reach $41.5 billion by 2027, emphasizing the importance of these machines in various sectors. One key benefit of using compressors in production processes is the optimization of energy consumption. Industrial compressors are designed to operate with high efficiency, significantly reducing energy costs. For instance, a study published by the U.S. Department of Energy indicates that an efficient compressor system can lead to energy savings of up to 30%, illustrating the potential for substantial cost reduction over time.

Additionally, compressors enhance the reliability and performance of manufacturing operations. They provide a consistent supply of compressed air, which is crucial for powering pneumatic tools, controlling machinery, and facilitating processes like material handling. Research by the Compressed Air and Gas Institute notes that maintaining optimal air pressure is essential for achieving maximum productivity and minimizing downtime. An efficient compressor system not only ensures smooth operations but also prolongs the lifespan of equipment, reducing maintenance costs and improving overall operational efficiency. With these advantages, industrial compressors emerge as a cornerstone of effective manufacturing processes, supporting businesses in achieving their production goals.

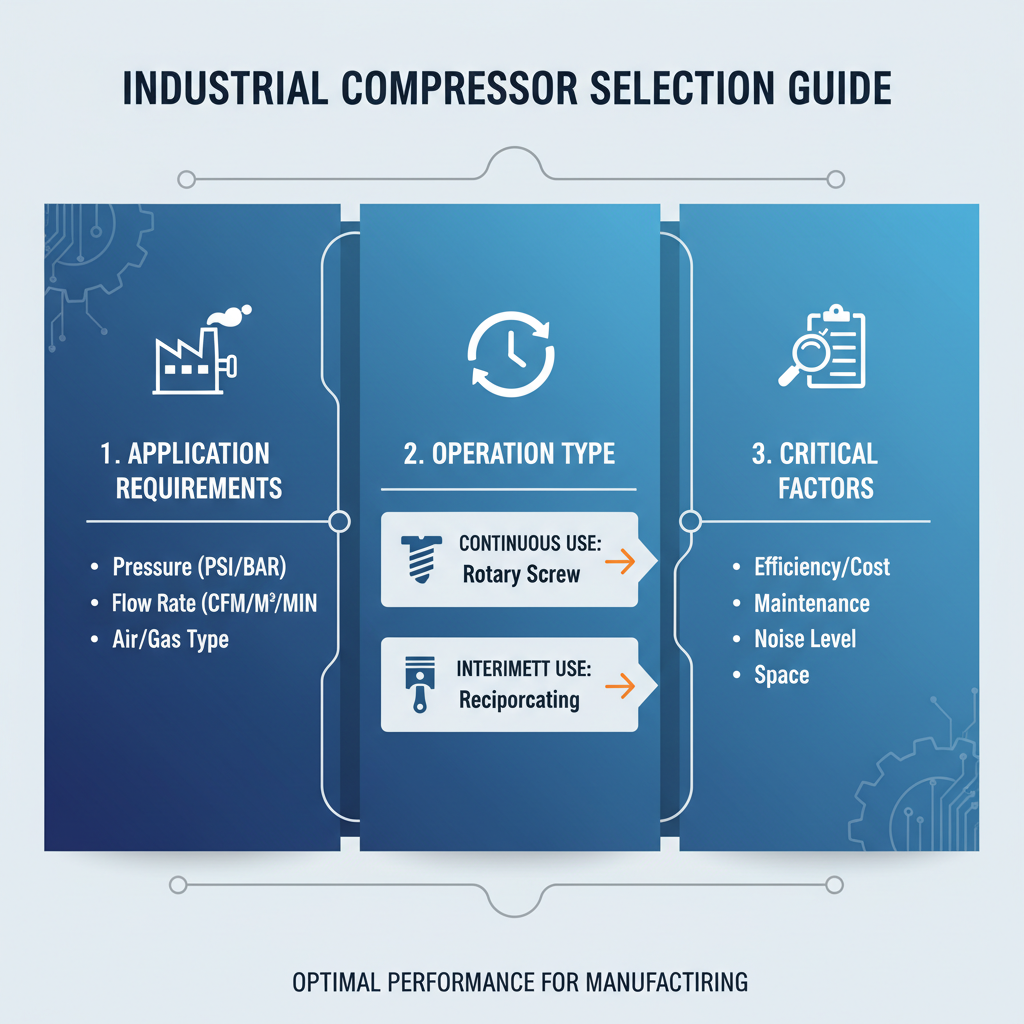

Factors to Consider When Selecting an Industrial Compressor

When selecting an industrial compressor, several critical factors should be taken into account to ensure optimal performance in manufacturing processes. Firstly, the application requirements must be clearly defined. The desired pressure, flow rate, and type of air or gas being compressed are fundamental considerations that influence the choice of compressor type and size. For instance, rotary screw compressors are preferred for continuous operation, while reciprocating compressors might be more suitable for intermittent use.

Another essential consideration is the compressor's energy efficiency. As the industrial air compressor market is projected to grow significantly, with estimates reaching up to $42.9 billion, the demand for energy-efficient solutions is paramount. Choosing a compressor that minimizes energy consumption not only reduces operational costs but also aligns with sustainability goals. Additionally, factors such as maintenance requirements, the operating environment, and the availability of replacement parts should be assessed to ensure long-term reliability and performance in various manufacturing settings.

Maintenance Practices for Optimizing Compressor Performance

Proper maintenance practices are crucial for optimizing the performance of industrial compressors, which play a significant role in manufacturing efficiency. According to the Compressed Air and Gas Institute (CAGI), proper maintenance can improve energy efficiency by up to 30%, reducing operational costs significantly. Regular checks on the compressor’s filters, oil levels, and pressure settings can help identify issues early, preventing costly downtime. Scheduled maintenance not only extends the lifespan of the compressor but ensures that the system operates at optimal efficiency, thus enhancing productivity.

Additionally, incorporating predictive maintenance techniques can further enhance compressor reliability. As per a report from the International Journal of Engineering Research and Applications, implementing predictive analytics can lead to a 20-30% reduction in maintenance costs by anticipating failures before they occur. Utilizing technology such as vibration analysis and thermal imaging helps in monitoring the compressor's condition in real time, allowing for timely interventions. By focusing on these maintenance strategies, manufacturers can achieve smoother operations and maintain high production levels, ultimately leading to increased profitability.

Why Industrial Compressors are Essential for Efficient Manufacturing Processes - Maintenance Practices for Optimizing Compressor Performance

| Maintenance Practice | Frequency | Benefits | Potential Issues |

|---|---|---|---|

| Oil Change | Every 500 hours | Improves lubrication and reduces wear | Increased friction and overheating |

| Air Filter Replacement | Every 3 months | Enhances air quality and system efficiency | Reduced airflow and pressure drops |

| Belt Inspection | Monthly | Prevents belt failure and downtime | Unexpected breakdowns |

| Vibration Analysis | Quarterly | Detects issues early to avoid major failures | Delayed reactions to anomalies |

| Condensate Drain Inspection | Bi-weekly | Prevents moisture buildup | Corrosion and system inefficiency |

Related Posts

-

Top 10 Industrial Air Solutions to Optimize Your Facility's Efficiency

-

Top 10 Industrial Compressors of 2023: Performance, Efficiency, and Reliability Insights

-

Why Pressure Gauges are Essential for Accurate Measurements in Various Industries

-

Maximize Efficiency: The Surge in Industrial Air Compressor Rental Demand for Sustainable Practices in Manufacturing

-

Maximizing Efficiency with Industrial Air Compressor Rental Services for Your Business Needs

-

How to Easily Find Affordable Compressor Repair Services in 2025

Copyright © 2025

I&M Industrials Inc.

10 Akron Drive

Greenville SC 29605

Phone: 864-277-2450

GSA Number – GS07F0379Y