1-800-868-2450

My Account | Cart | Checkout

2026 How to Choose the Best Air Compressor Oil for Optimal Performance?

Choosing the right air compressor oil is essential for optimal performance. This oil lubricates the moving parts, reducing wear and tear. A high-quality oil ensures efficient operation and extends your compressor's lifespan. However, many users overlook the importance of selecting the right oil.

Different compressors require different oil types. Synthetic oils offer superior protection, while mineral oils are more affordable. It's vital to consider your compressor's specifications before making a choice. Pay attention to the viscosity grade as well.

Some people may rush their decision, impacting performance. Over time, using the wrong oil can lead to increased friction and overheating. Take the time to research and choose wisely. The right air compressor oil can make a notable difference in your machine's efficiency. Do not underestimate its significance.

Understanding the Importance of Air Compressor Oil for Performance

Air compressor oil plays a crucial role in ensuring optimal performance. This oil lubricates the moving parts, reducing friction and wear. According to industry reports, using the correct type of oil can increase compressor efficiency by up to 20%. This increase can lead to significant energy savings over time.

Choosing the right oil is not just about viscosity. The oil should match the compressor type and operating conditions. For example, synthetic oils offer superior protection and efficiency compared to conventional oils. On the other hand, not all synthetic oils are compatible with every compressor type. Users must check compatibility.

Tips: Always refer to the manufacturer’s specifications when selecting oil. Regularly monitor oil levels and look for signs of degradation. Changing the oil regularly not only enhances performance but also extends the life of the unit. If in doubt, seek advice from a professional. Every compressor needs different care, and neglecting this can lead to costly repairs.

Identifying Different Types of Air Compressor Oils Available in the Market

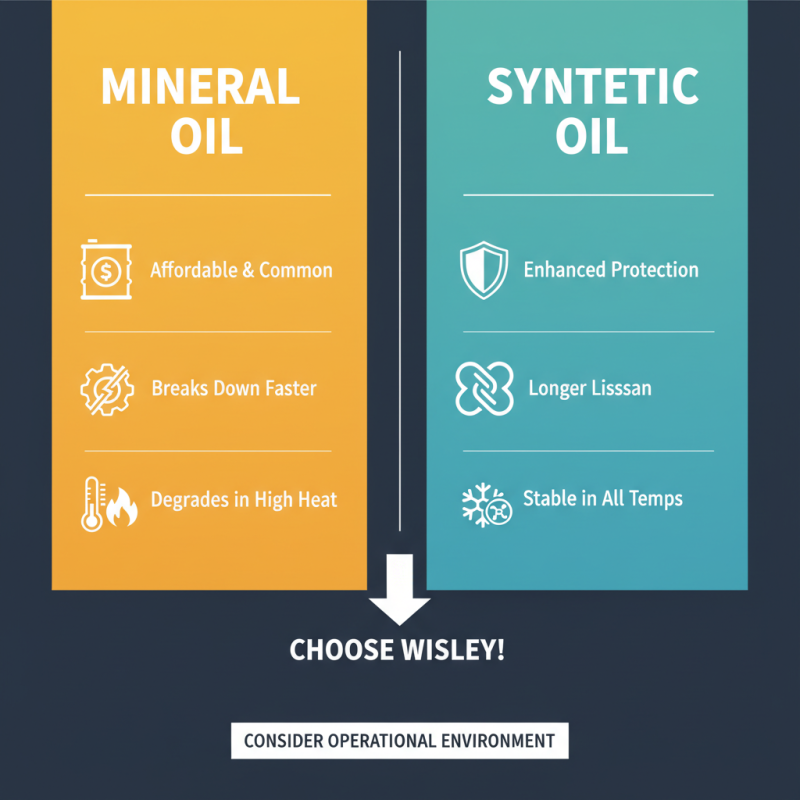

When selecting air compressor oil, it’s crucial to understand the different types available. Mineral oil is the most common type. It’s affordable and works for many applications. However, it may break down quicker than synthetic oils. Users should consider their operational environment. High temperatures can cause mineral oils to degrade faster.

Synthetic oil offers greater stability and longevity. It provides better performance in extreme conditions. However, it often comes at a higher price point. Some users find it tough to gauge the needed balance between cost and effectiveness. Careful evaluation is essential.

Tips: Always check the viscosity rating. It affects the oil's flow and protection. Ensure the oil suits your compressor type. Look for user reviews and expert advice. This can guide you to make better decisions. Remember, choosing the wrong oil may lead to costly repairs. Regular maintenance is key to optimizing performance.

Key Factors to Consider When Selecting Air Compressor Oil

Choosing the right air compressor oil is crucial for maintaining optimal performance. Several key factors can guide your decision. The oil's viscosity is one of them. It affects how the oil flows under different temperatures. Thicker oils may provide better lubrication in hot conditions but could hinder performance in colder climates.

Another important consideration is the oil's formulation. Synthetic oils often offer superior protection and extend equipment life. They tend to resist breakdown better than mineral oils. However, these can be pricier. You might find yourself questioning if the benefits justify the cost.

Finally, pay attention to the manufacturer's recommendations. Each compressor is designed with specific oil types in mind. Using the incorrect oil can lead to increased wear and tear. Sometimes, people overlook this detail, thinking all oils are interchangeable. It’s vital to ensure compatibility for the best results. A moment of oversight can lead to costly repairs.

Compatibility of Air Compressor Oil with Specific Compressor Types

Choosing the right air compressor oil is crucial for optimal performance. Compatibility with your specific compressor type is essential. Different compressors have unique requirements. Using the wrong oil can lead to poor performance and damage. For example, rotary screw compressors often need specially formulated oils. These oils reduce friction and wear, essential for their continuous operation.

Piston compressors, on the other hand, may require alternative oil types. Regular motor oils might not suffice. They can break down quickly under high temperatures. This breakdown can cause overheating, leading to equipment failure. It’s vital to check the manufacturer's guidelines. Each compressor type has specific oil needs. Not all oils will perform equally well.

Making the right choice isn’t always easy. Sometimes, users feel confident in their selections, only to find issues later. Conducting research is necessary. Consider viscosity levels and additives. Oil with the wrong viscosity can affect performance. If in doubt, consult professionals or experienced users. Your choice of oil directly impacts the longevity and efficiency of your compressor.

Maintenance Tips for Optimal Use of Air Compressor Oil

Proper maintenance of air compressor oil is crucial for optimal performance. Regularly check the oil level to ensure it is adequate. Low oil levels can lead to overheating and increased wear. Change the oil based on usage; some users might find they need to change it more frequently than they expected. Pay attention to the color and consistency of the oil. Dark, dirty oil indicates contamination and reduced efficiency.

In addition, always incorporate the right type of oil based on your compressor model. There are various types available, and not all are suitable for every compressor. Using the wrong oil can lead to severe damage. Storing oil properly is equally important; keep it in a cool, dry place. This can prevent degradation over time. Check for recommended practices in the user manual.

Be mindful of the air filter as well. A clogged filter can lead to increased pressure and additional stress on the oil. Periodic cleaning or replacing filters can improve the overall system efficiency. Sometimes, it may feel tedious, but neglecting these small details can lead to bigger issues. Even the most diligent maintenance routines can miss these aspects, so awareness is key.

Related Posts

-

2025 How to Choose the Best Air Compressor Oil for Optimal Performance

-

Best Air Compressor Oil for Optimal Performance and Longevity?

-

2026 Best Air Compressor Oil Reviews and Buying Guide?

-

Top 10 Benefits of Compressed Air Piping Systems for Your Business

-

How to Easily Find Affordable Compressor Repair Services in 2025

-

Top 10 Industrial Compressors of 2023: Performance, Efficiency, and Reliability Insights

Copyright © 2025

I&M Industrials Inc.

10 Akron Drive

Greenville SC 29605

Phone: 864-277-2450

GSA Number – GS07F0379Y