1-800-868-2450

My Account | Cart | Checkout

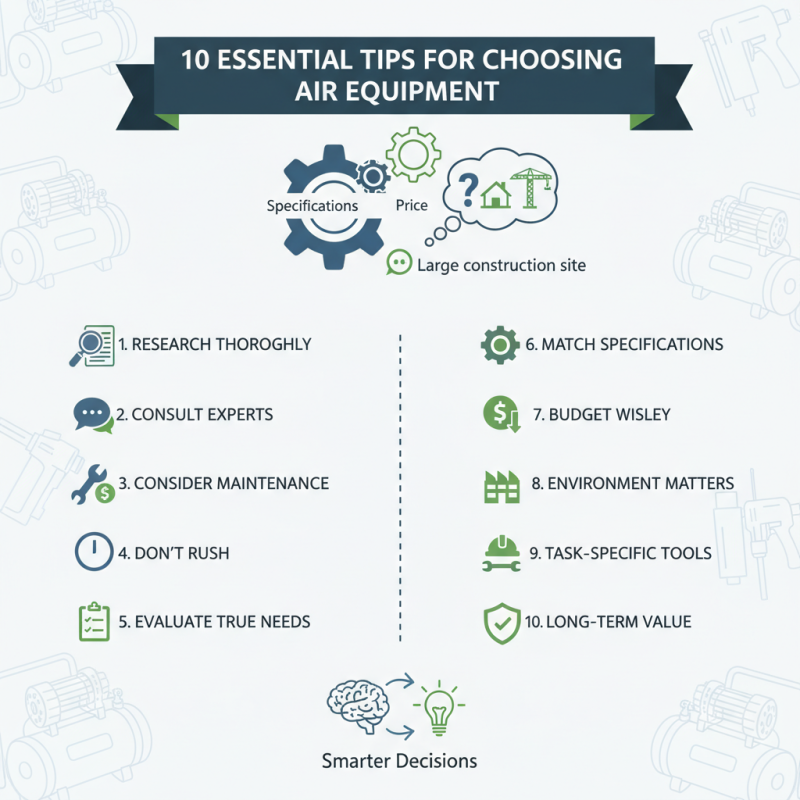

10 Essential Tips for Choosing the Right Air Equipment for Your Needs?

Choosing the right air equipment can greatly impact your projects. The market is filled with options. Each choice comes with different specifications, prices, and purposes. It can feel overwhelming.

Consider your specific needs carefully. This means understanding your environment and tasks. Are you working in a small workshop or a large construction site? The demands will differ significantly. Moreover, think about maintenance costs. Cheaper options may lead to higher long-term expenses.

Don't rush into buying. Take your time to research. Consult with experts if needed. Mistakes can be costly, and the wrong equipment may hinder your progress. Evaluate what you truly require before making a commitment. This approach will lead to smarter, more effective decisions in selecting air equipment.

Understanding Your Air Equipment Requirements

Choosing the right air equipment starts with understanding specific needs. Assess your environment first. Indoor systems differ from outdoor ones. For example, dust levels impact filter choices significantly. A report by the National Air Filtration Association suggests that 80% of indoor air quality issues stem from filtration inefficiencies.

Size also matters when selecting air equipment. Underestimating the required airflow can lead to inefficient performance. According to the U.S. Department of Energy, an improperly sized air system can increase energy costs by 30%. Many overlook maintenance needs, which can lead to costly repairs down the line. Regular checks can extend the lifespan of your equipment.

Don’t forget about noise levels. A quieter system might enhance comfort but could compromise performance. Some users struggle with balancing efficiency and sound levels. A study by the Environmental Protection Agency highlights how noise pollution affects productivity and well-being. It’s essential to weigh these factors carefully to ensure that your choice truly meets your air quality needs.

10 Essential Tips for Choosing the Right Air Equipment for Your Needs

| Tip Number | Tip Description | Considerations | Suitable For |

|---|---|---|---|

| 1 | Define Your Air Demand | Assess total air consumption requirements | Manufacturers, Workshops |

| 2 | Understand Air Quality Standards | Know the level of filtration required | Food Processing, Pharmaceutical |

| 3 | Analyze Energy Efficiency | Consider energy ratings and potential savings | All Industries |

| 4 | Choose the Right Size | Avoid oversized or undersized equipment | Construction, Manufacturing |

| 5 | Consider Noise Levels | Look for quieter models for sensitive environments | Offices, Residential Areas |

| 6 | Opt for Versatile Equipment | Equipment that can handle multiple applications | Small Businesses, Workshops |

| 7 | Check for Maintenance Requirements | Identify easy-to-maintain models | All Industries |

| 8 | Explore Advanced Features | Look for features like load sensors and smart controls | Tech-Savvy Organizations |

| 9 | Assess the Cost of Ownership | Consider long-term costs beyond initial purchase | All Industries |

| 10 | Read Customer Reviews | Analyze user feedback and case studies | All Potential Buyers |

Evaluating Different Types of Air Equipment

When evaluating different types of air equipment, begin by assessing your specific requirements. According to industry reports, 45% of users prioritize energy efficiency in their selection. This factor can drastically lower operational costs over time. Understanding your usage pattern is crucial. For instance, if you only need equipment for occasional tasks, a portable air compressor might suffice. Alternatively, continuous applications may require a more robust fixed unit.

The type of air equipment you choose will also depend on the environment. For example, environments with high dust levels necessitate specialized filters. Data suggests that 30% of equipment failures arise from improper filtration. The right filtration system can prevent breakdowns and extend the equipment's lifespan. Reflecting on your operational conditions can lead to more effective equipment selections and avoid costly mistakes. Many employers overlook this and end up with unsuitable machines, causing inefficiencies and unexpected expenses.

10 Essential Tips for Choosing the Right Air Equipment for Your Needs

Assessing the Performance and Efficiency Ratings

When it comes to selecting air equipment, performance and efficiency ratings are crucial. These ratings provide insight into how well a machine operates under various conditions. Understanding these metrics can be daunting. Many people overlook the importance of these ratings, leading to poor purchasing decisions.

Efficiency ratings often use a standardized scale. This allows for easy comparisons between different models. Look for tools that highlight energy consumption. A model with a high efficiency rating can save money in the long run. However, the most efficient option is not always the best for your specific needs. Sometimes, higher efficiency comes with reduced functionality. You may find yourself compromising on other features that matter.

Performance ratings should be examined closely. They reveal how well the equipment performs tasks such as air delivery and pressure outputs. A piece of equipment might score highly on efficiency but underperform in actual usage. This leads to frustration and unmet expectations. Pay attention to user reviews and real-world testing. They often provide insights that factory ratings do not capture. Balancing efficiency with practical performance is key to making an informed choice.

Considering Maintenance and Service Support Options

When choosing air equipment, maintenance and service support are crucial. Proper maintenance ensures longevity and efficiency. Consider how often the equipment will need servicing. Some systems require frequent checks, while others can go longer between services. Think about your schedule and staff availability for maintenance tasks.

Evaluate the service support options available. Some companies offer onsite support, while others provide remote assistance. Quick response times are vital when issues arise. Having access to knowledgeable technicians can reduce downtime significantly. Explore warranty options as well. A strong warranty often reflects confidence in the product.

Don't overlook user reviews and experiences related to maintenance. They often highlight potential issues. Ask other users about their experiences with support. A well-supported air system can save you from future headaches. Be sure to understand the full scope of ongoing costs for maintenance.

Budgeting for Air Equipment Purchase and Operating Costs

When budgeting for air equipment, consider initial purchase costs and ongoing operation costs. A recent industry report outlines that operating costs can account for up to 30% of a system's total lifetime expenses. This makes it critical to understand all financial implications before making a decision.

Tip: Look into energy efficiency ratings. Equipment with higher ratings may have a higher upfront cost. However, the savings on energy bills can be substantial over time. Consider lifecycle costs rather than only the initial price.

Also, assess maintenance needs. Regular maintenance is crucial for optimal performance. A machine requiring frequent repairs can lead to increased costs. The same report indicates that neglected machinery can consume up to 20% more energy. It’s essential to weigh these factors in your financial planning.

Lastly, explore financing options. Leasing equipment can spread out costs over time, making it more manageable. Know that some financing options come with hidden costs. Understanding the total cost of ownership will ultimately lead to better budgeting and choice in equipment.

Related Posts

-

Top 10 Industrial Air Solutions to Optimize Your Facility's Efficiency

-

Why Process Equipment is Essential for Efficient Industrial Operations

-

Top 10 Industrial Compressors of 2023: Performance, Efficiency, and Reliability Insights

-

How to Choose the Best Air Pressure Gauge for Your Needs in 2025

-

2025 Top Industrial Air Compressors: Key Features and Buying Guide

-

Top 10 Benefits of Screw Compressor Oil for Performance?

Copyright © 2025

I&M Industrials Inc.

10 Akron Drive

Greenville SC 29605

Phone: 864-277-2450

GSA Number – GS07F0379Y