1-800-868-2450

My Account | Cart | Checkout

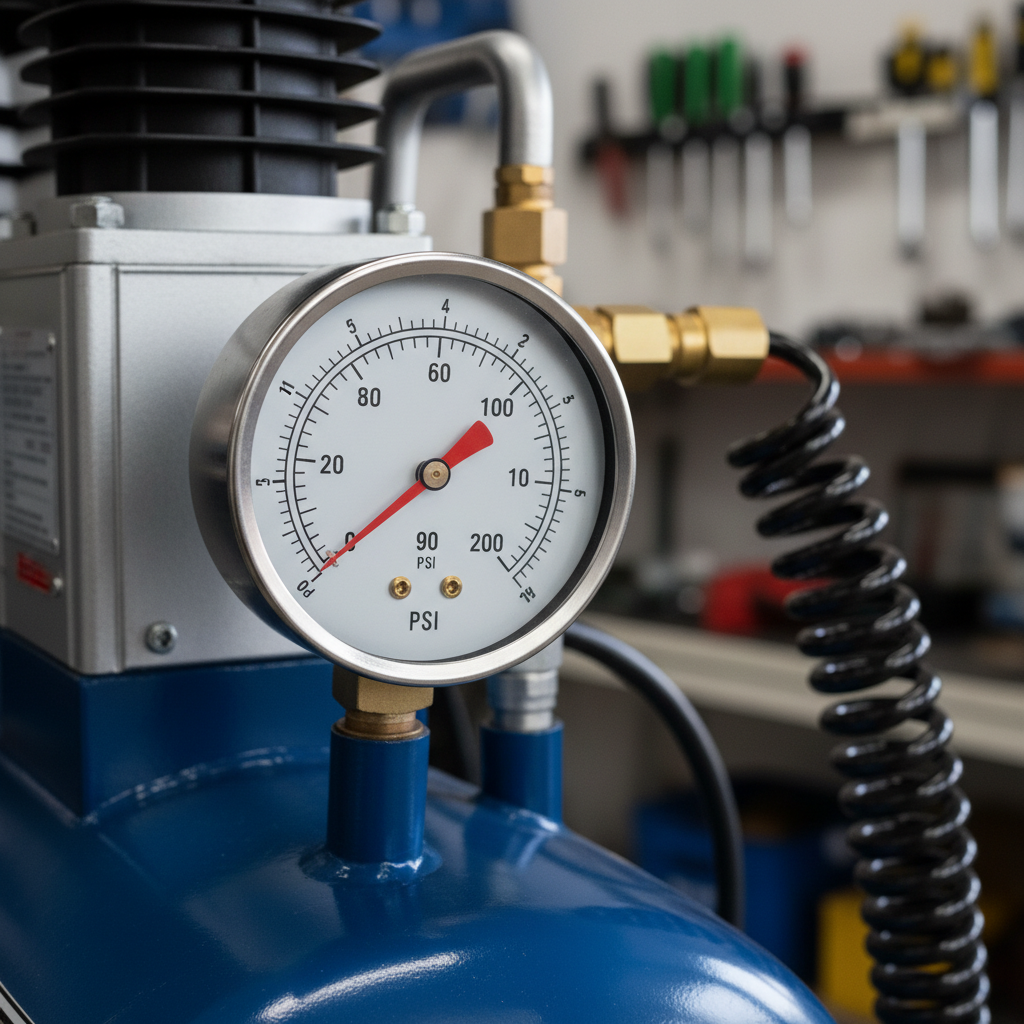

10 Essential Tips for Accurately Reading Your Air Compressor Gauge

Understanding how to read your air compressor gauge accurately is crucial for any project that requires compressed air. Whether you are a professional mechanic, a DIY enthusiast, or simply using an air compressor for home tasks, the right pressure reading can make a significant difference in performance and efficiency. An incorrectly set or misread air compressor gauge can lead to equipment damage, safety hazards, and suboptimal results in your work.

In this guide, we will explore ten essential tips for mastering the art of reading your air compressor gauge. From understanding the gauge's measurement units to recognizing when it's time for maintenance, this comprehensive list will equip you with the knowledge needed to optimize your air compressor usage. Gaining confidence in how to interpret your air compressor gauge will not only enhance your skills but also ensure that you achieve the best outcomes for your projects. So, let's dive into these invaluable tips that will help you elevate your air compressor experience.

Understanding Your Air Compressor's Pressure Gauge Types

Understanding the various types of pressure gauges on your air compressor is crucial for ensuring accurate readings and optimal performance. Most air compressors utilize either analog or digital gauges. Analog gauges are the traditional type, using a needle to indicate pressure on a dial. According to a report by the Compressed Air and Gas Institute, analog gauges are favored in many industrial applications for their durability and simplicity. However, they can be less precise than digital ones, especially at lower pressure levels, where the needle may be hard to read accurately.

On the other hand, digital gauges provide a more precise and easy-to-read measurement of air pressure. These gauges often come with features such as backlit displays, which enhance visibility in dimly lit environments, and the ability to set predetermined pressure levels. A study from the American Society of Mechanical Engineers indicates that using digital gauges can reduce misreadings by up to 30%, making them a safe choice for both amateur and professional users. Understanding the differences between these gauge types can significantly impact the maintenance and efficiency of your air compressor, ensuring better performance and longevity.

Common Mistakes to Avoid When Reading Air Compressor Gauges

When it comes to operating an air compressor, accurately reading the gauge is crucial for achieving optimal performance and ensuring safety. One common mistake users make is not positioning themselves at eye level with the gauge. This can lead to parallax error, which occurs when the reading is misinterpreted due to the angle of view. A study by the American Society of Mechanical Engineers found that 30% of operators encountered discrepancies in pressure readings, primarily due to improper gauge alignment. Always ensure that you are viewing the gauge directly to avoid misreading critical data.

Another frequent error is overlooking the temperature correlation with pressure readings. Gauge accuracy can be affected by temperature fluctuations, leading to potential overinflation or underinflation of the tank. According to the National Institute for Occupational Safety and Health, maintaining proper thermal conditions around compressor gauges can enhance accuracy by up to 15%. Thus, it's vital to monitor environmental conditions while assessing pressure levels.

Additionally, users often neglect to regularly calibrate their gauges. Calibration is essential for maintaining the precision of your readings and ensuring that your equipment operates efficiently. Engaging in regular calibration checks can prevent up to 25% of pressure-related accidents. By following these tips, you can significantly enhance the accuracy of your air compressor gauge readings.

How to Interpret PSI Readings for Optimal Performance

Understanding PSI readings on your air compressor gauge is crucial for maintaining optimal performance and extending the lifespan of your equipment. PSI, or pounds per square inch, measures the pressure of the air in your compressor. Accurate interpretation of these readings can prevent issues such as over-pressurization, which not only risks damaging your tools but can also compromise safety. According to a recent industry report by the Air Compression Association, improper PSI levels account for nearly 30% of mechanical failures in air compressors.

One of the essential tips for accurately reading your compressor gauge is to always allow the compressor to reach its cutoff pressure before taking a measurement. This ensures that the reading you see is stable and representative of the compressor's performance. Furthermore, it’s advisable to routinely calibrate your gauge, as even small discrepancies can lead to significant issues over time. Regular maintenance checks, as suggested by the Equipment Manufacturers Association, should be performed at least quarterly to ensure your system remains efficient.

Another vital tip is to familiarize yourself with the specific PSI requirements of the tools you frequently use. Each tool has a designated PSI range for optimal performance; exceeding or falling short of this range can lead to inefficiencies or equipment damage. A study from the National Institute for Occupational Safety and Health reveals that operating tools at recommended PSI levels can enhance productivity by 20%, emphasizing the importance of proper gauge interpretation for both performance and safety.

10 Essential Tips for Accurately Reading Your Air Compressor Gauge

| Tip Number | Tip Description | PSI Reading | Optimal Performance |

|---|---|---|---|

| 1 | Check the Gauge Regularly | 90-100 PSI | Good for most tools |

| 2 | Calibrate Your Gauge | 0-120 PSI | Ensure accuracy |

| 3 | Understand the Color Codes | Green Zone: 90-120 PSI | Ideal for operation |

| 4 | Check for Leaks | Above 100 PSI | Resolve to prevent drop |

| 5 | Adjust According to Tool | 30-90 PSI | For nail guns |

| 6 | Mind Temperature Changes | Check in cold/hot | Expect variations |

| 7 | Inspect Connections | Maintain > 80 PSI | Secure connections |

| 8 | Know Your Tools | 150-200 PSI | For heavy-duty tools |

| 9 | Avoid Over-Inflation | >200 PSI | Potentially damaging |

| 10 | Routine Maintenance | Check monthly | Ensure longevity |

Tips for Maintaining Accurate Air Compressor Gauge Readings

Maintaining accurate air compressor gauge readings is crucial for the effective operation of your air compressor. One key tip is to regularly inspect the gauge for any signs of damage or wear. A compromised gauge can lead to misreadings, which may affect the overall performance of your compressor. If you notice any inconsistencies in the readings, consider replacing the gauge to ensure reliability.

Another important aspect is to routinely check for air leaks in the system. Even minor leaks can cause pressure fluctuations, resulting in inaccurate gauge readings. To do this, apply a mixture of soapy water to the connections and fittings. Bubbles will form if there are any leaks, allowing you to fix them promptly and maintain correct pressure levels.

Lastly, calibrating your gauge regularly can help sustain its accuracy. Each time you service your compressor, take the time to compare the gauge readings with a certified pressure gauge. If discrepancies are found, recalibrating or replacing the gauge can prevent operational issues down the line, ensuring your air compressor remains efficient and reliable.

Essential Tools for Troubleshooting Air Compressor Gauges

When troubleshooting air compressor gauges, having the right tools on hand is crucial for accurate diagnostics and efficient repairs. A high-quality pressure gauge is essential as it allows for precise readings, which can help identify issues such as leaks or faulty compressor performance. Additionally, a multi-meter can be invaluable, especially when assessing electrical components within the air compressor system. This tool can help determine if there are any electrical faults that could affect gauge functionality.

Another important tool for troubleshooting is a leak detector solution. This solution can be applied to connections and hoses to identify any leaks that might skew gauge readings. If leaks are detected, they will need to be repaired to ensure the accuracy of the gauge. Lastly, having an adjustable wrench and various socket sizes will aid in disassembling and reassembling components as necessary during the troubleshooting process. With these essential tools, maintaining and accurately reading your air compressor gauge becomes more manageable, helping to enhance the overall efficiency and reliability of your air compressor system.

Related Posts

-

The Future of Industrial Air Compressor Technology Innovations to Watch

-

Top 5 Compressed Air Solutions to Boost Your Business Efficiency

-

Top 10 Industrial Compressors of 2023: Performance, Efficiency, and Reliability Insights

-

Unlocking the Power of High Pressure Air Compressors for Home and Industry

-

Top 10 Industrial Air Solutions to Optimize Your Facility's Efficiency

-

How to Easily Find Affordable Compressor Repair Services in 2025

Copyright © 2025

I&M Industrials Inc.

10 Akron Drive

Greenville SC 29605

Phone: 864-277-2450

GSA Number – GS07F0379Y