1-800-868-2450

My Account | Cart | Checkout

How to Effectively Maintain Your Air Compressor for Optimal Performance

In the field of industrial equipment, air compressors play a crucial role in enhancing productivity and efficiency. As noted by industry expert John Smith, “Proper air compressor maintenance can significantly extend the life of your machinery and improve operational reliability.” This statement underscores the importance of regular upkeep and care for air compressors, which are vital in various applications, from manufacturing to construction.

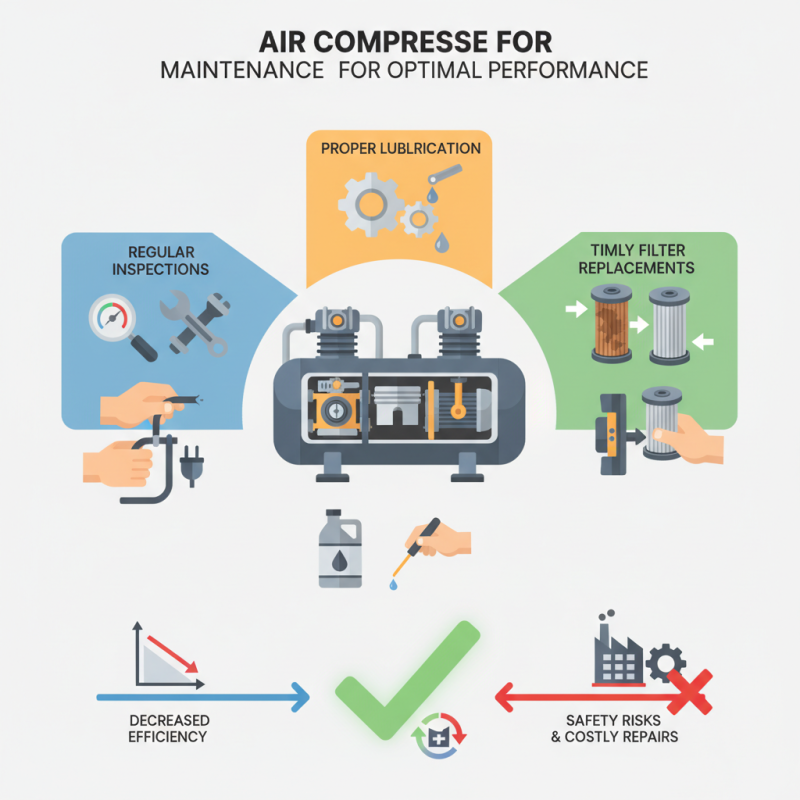

Maintaining an air compressor goes beyond mere routine check-ups; it encompasses a systematic approach to ensuring optimal performance. Key maintenance practices include regular inspections, proper lubrication, and timely filter replacements. Without these essential steps, air compressors may suffer from decreased efficiency, leading to increased energy consumption and potentially costly repairs.

Furthermore, neglecting air compressor maintenance not only impacts the equipment's functionality but also poses safety risks in the workplace. This highlights the necessity for businesses to implement comprehensive maintenance strategies that safeguard both their investments and their workforce. By prioritizing air compressor maintenance, organizations can achieve unparalleled efficiency and reliability, ensuring their operations run smoothly for years to come.

Understanding the Basic Components of an Air Compressor

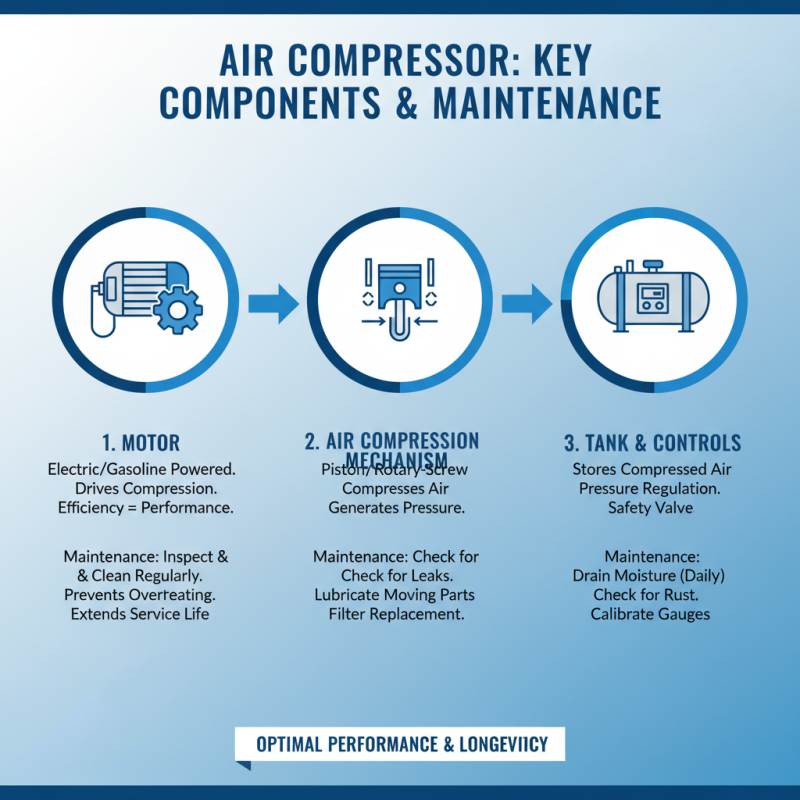

Understanding the basic components of an air compressor is essential for ensuring its optimal performance and longevity. At the heart of any air compressor is the motor, which drives the mechanism that compresses air. The motor can be electric or gasoline-powered, and its efficiency directly affects the overall performance of the compressor. Proper maintenance of the motor, including regular inspections and cleanings, is crucial to prevent overheating and extend its service life.

Another key component is the air receiver tank, which stores compressed air and helps to regulate the flow, preventing fluctuations in pressure during operation. It's essential to check the tank regularly for any signs of corrosion or damage, as this can significantly impact its efficiency and safety. Additionally, the pressure switch controls the pressure levels within the system, ensuring that the compressor functions within the desired range. Regularly testing and calibrating this switch can help maintain uniform performance and prevent the compressor from working harder than necessary.

Filters are also vital components that help maintain air quality by removing moisture and contaminants. Keeping these filters clean and replacing them as needed promotes better airflow and compressor efficiency. Moreover, understanding and caring for components like the regulator and safety valves ensures the system operates smoothly and safely, ultimately leading to enhanced performance and reliability of the air compressor.

Establishing a Regular Maintenance Schedule for Air Compressors

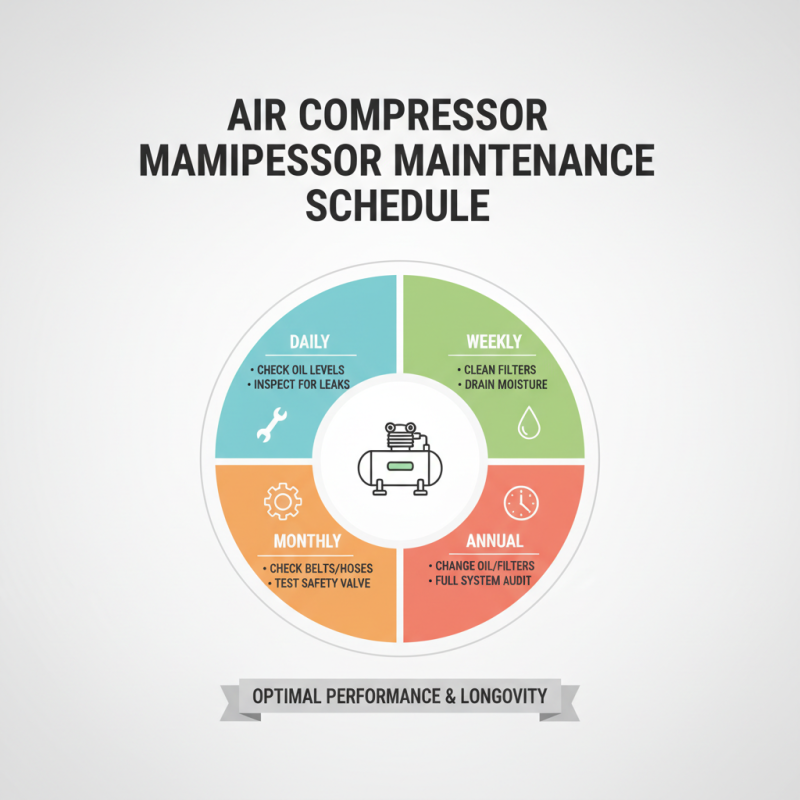

Establishing a regular maintenance schedule for air compressors is crucial for ensuring their optimal performance and longevity. By regularly checking and servicing your air compressor, you can prevent issues before they arise, saving time and money in the long run. Begin by creating a maintenance calendar that outlines daily, weekly, monthly, and annual tasks. Daily checks might include inspecting oil levels and ensuring there are no air leaks, while weekly maintenance can involve cleaning filters and draining moisture from the tank.

In addition to these routine checks, it's essential to provide thorough inspections on a monthly basis. This includes checking the belt tensions, inspecting electrical connections, and monitoring the cooling system. Over time, components can wear down and may require replacement to maintain efficiency. Annual maintenance should include a professional evaluation, which can help identify potential problems that might not be visible during regular checks. By committing to this structured approach, you will not only enhance the performance of your air compressor but also extend its lifespan.

Key Maintenance Tasks for Optimal Air Compressor Functionality

To ensure your air compressor operates at peak efficiency, it’s essential to carry out regular maintenance tasks.

First and foremost, routinely check and change the air filter. A clogged filter restricts airflow, which can lead to decreased performance and increased energy consumption. Depending on usage, the filter should be inspected monthly and replaced as necessary. Additionally, ensure that the air intake and exhaust vents are free from debris, allowing for unhindered airflow.

Another critical maintenance task is to inspect and tighten all connections and fittings. Loose fittings can lead to air leaks, resulting in wasted energy and reduced operational capacity. Regularly examining hoses for signs of wear or damage can prevent unexpected downtime.

Furthermore, draining the moisture from the air tank is vital, as accumulated water can cause corrosion and affect the quality of the compressed air.

Performing these maintenance tasks consistently will amplify the longevity and reliability of your air compressor, keeping it running smoothly and efficiently.

Troubleshooting Common Air Compressor Issues and Solutions

When using an air compressor, encountering issues is not uncommon. One of the most common problems is inadequate pressure output. This can often be traced back to a dirty air filter or a worn-out pressure switch. Regularly inspecting and replacing the air filter will ensure the compressor receives an ample air supply. Additionally, checking the pressure switch for any signs of wear or malfunction can prevent pressure inconsistencies, allowing for optimal performance.

Another frequent issue is excessive noise or vibrations during operation, which can indicate problems with the internal components or mounting hardware. Tightening loose parts and ensuring proper lubrication can help eliminate these disturbances. It’s also crucial to monitor for any air leaks in the hoses or fittings, as these can lead to decreased efficiency and increased energy costs. Regularly checking connections and using sealant or tape can help maintain a tight seal and enhance the overall performance of the air compressor.

How to Effectively Maintain Your Air Compressor for Optimal Performance - Troubleshooting Common Air Compressor Issues and Solutions

| Issue | Symptoms | Possible Causes | Solutions |

|---|---|---|---|

| Compressor Not Starting | No noise, no air | Faulty power supply, blown fuse | Check power source and fuses; reset circuit breaker |

| Low Air Pressure | Inadequate output | Leaky hoses, worn-out seals | Inspect hoses and fittings; replace worn components |

| Excessive Noise | Loud operation | Loose parts, damaged motor | Tighten bolts and screws; check for mechanical damage |

| Overheating | High temperature, shut down | Blocked air intake, low oil | Clear intake; check and refill oil levels |

| Oil Leaks | Visible oil puddles | Worn seals or gaskets | Replace seals and gaskets; monitor regularly |

Safety Precautions When Maintaining Your Air Compressor

When maintaining your air compressor, prioritizing safety is crucial to ensure both the functionality of the machine and the well-being of the operator. Before starting any maintenance tasks, make sure to disconnect the compressor from its power source. This prevents accidental activation and helps avoid potential injuries. Additionally, bleed the air tank to release any built-up pressure. This step is vital to prevent explosions and ensure safer working conditions.

While working on the compressor, always wear appropriate personal protective equipment (PPE) such as safety goggles and gloves to shield yourself from debris and sharp edges. It's also essential to have a well-ventilated workspace to avoid inhaling any harmful dust and particles that may be released during maintenance. Keep a first-aid kit nearby in case of emergencies and familiarize yourself with its contents. By adhering to these safety precautions, you can significantly reduce the risk of accidents and ensure a smooth maintenance process for your air compressor.

Related Posts

-

Maximizing Efficiency: How Industrial Air Compressors Transform Manufacturing Processes

-

Maximize Efficiency: The Surge in Industrial Air Compressor Rental Demand for Sustainable Practices in Manufacturing

-

Why Industrial Compressors are Essential for Efficient Manufacturing Processes

-

Why Pressure Gauges are Essential for Accurate Measurements in Various Industries

-

Maximizing Efficiency with Industrial Air Compressor Rental Services for Your Business Needs

-

Top 5 Compressed Air Solutions to Boost Your Business Efficiency

Copyright © 2025

I&M Industrials Inc.

10 Akron Drive

Greenville SC 29605

Phone: 864-277-2450

GSA Number – GS07F0379Y