1-800-868-2450

My Account | Cart | Checkout

What is Compressor Maintenance and Why is it Important?

Compressor maintenance is a critical aspect of ensuring optimal performance in industrial settings. Compressors are vital for various operations, providing the necessary pressure for equipment. However, neglecting maintenance can lead to unexpected failures. Regular checks can prevent costly downtimes.

The consequences of poor compressor maintenance can be severe. A malfunctioning compressor can disrupt production. It often results in increased energy costs and waste. Noticing small issues early can save time and money.

Moreover, investing in compressor maintenance enhances efficiency. Well-maintained equipment runs smoother and lasts longer. This not only boosts productivity but also reduces replacement costs. Maintaining compressors is essential for business longevity and operational success.

What is Compressor Maintenance?

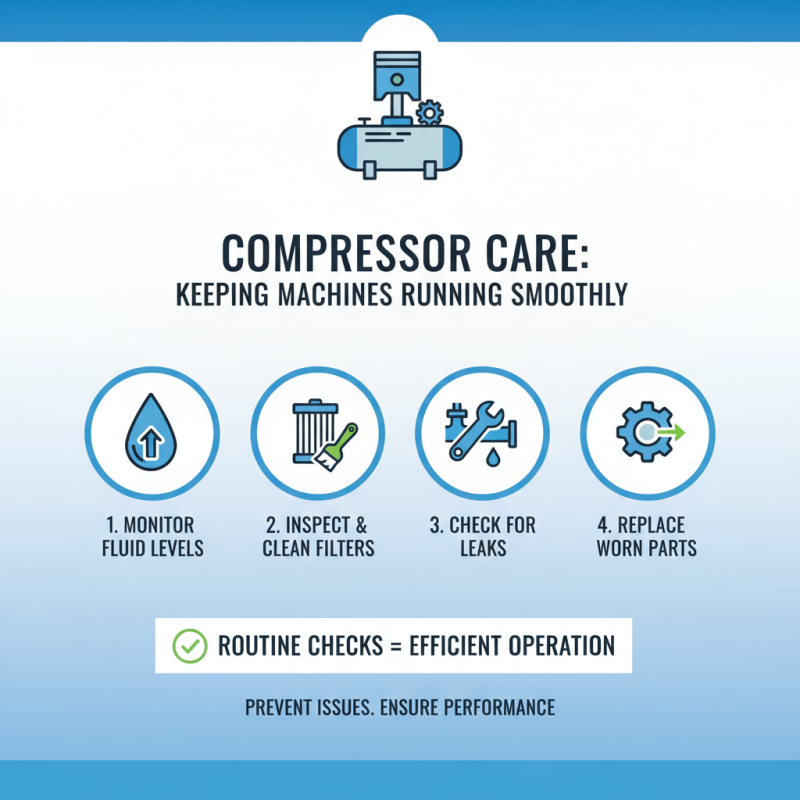

Compressor maintenance refers to the routine practices needed to keep compressors functioning efficiently. These machines play crucial roles in many industrial processes by compressing air or gas. Regular checks help ensure that they continue to perform well. This includes monitoring fluid levels, inspecting filters, and checking for leaks. Simple actions, like cleaning or replacing parts, can often prevent larger issues down the line.

Each component in a compressor can wear out over time. Ignoring these signs may lead to costly breakdowns. Unscheduled downtime can disrupt production schedules. It’s easy to overlook small issues until they escalate. Developing a maintenance schedule can help in addressing potential problems before they worsen. Keeping records of inspections and repairs is essential for effective management of compressor systems. Frequent evaluations enhance the lifespan of compressors and save expenses.

The Role of Compressors in Industrial Applications

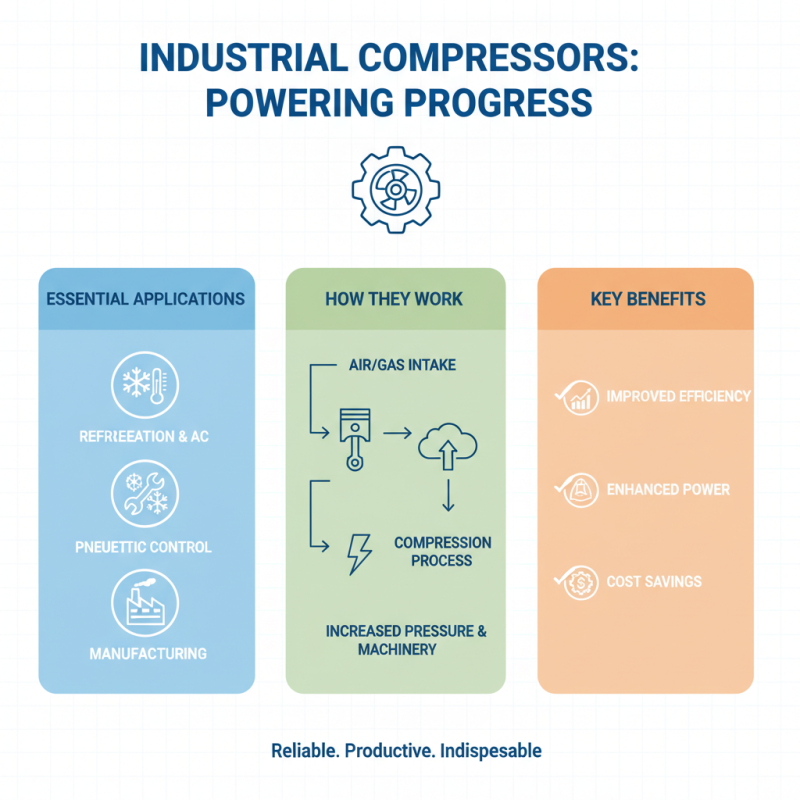

Compressors play a vital role in various industrial applications. They are essential for processes like refrigeration, air conditioning, and pneumatic control. In manufacturing, compressors increase efficiency by compressing air or gas. This process powers machinery and tools.

Without well-maintained compressors, operations can suffer. An inefficient compressor can increase energy costs. It may also lead to unexpected breakdowns. These failures disrupt production and can result in financial losses. Regular maintenance is crucial. It includes checking for leaks, inspecting belts, and replacing worn-out filters.

Industries sometimes overlook compressor care. Maintenance is often seen as an additional task. This approach can be flawed. Ignoring small issues can lead to bigger problems later. It is a chance to reflect on how we prioritize equipment health. A proactive approach can enhance productivity and reduce downtime.

Key Components of a Compressor and Their Maintenance

Compressor maintenance focuses on several key components. Regular monitoring can prevent costly breakdowns. The primary parts include the motor, valves, and filters. Each deserves specific attention. Neglecting any part can lead to failures.

The motor is crucial. According to industry data, about 30% of compressor issues stem from motor failure. Regular inspections can identify wear and tear early. Clean electrical connections and lubricated bearings extend lifespan. Valves control airflow, so grime build-up is problematic. A study showed that dirty valves could reduce efficiency by up to 15%.

Filters also require routine checks. Clogged filters can restrict airflow, leading to overheating. Reports indicate that nearly 40% of compressors run inefficiently due to dirty filters. Replacing filters regularly ensures optimal performance. While maintenance can be time-consuming, it’s a necessary investment. Many overlook simple tasks. This often results in bigger issues later on.

What is Compressor Maintenance and Why is it Important?

| Component | Function | Maintenance Frequency | Common Issues | Importance of Maintenance |

|---|---|---|---|---|

| Air Filter | Prevents dust and debris from entering the compressor. | Monthly | Clogging, reduced airflow | Ensures optimal air quality and efficiency. |

| Oil Separator | Separates oil from the compressed air. | Quarterly | Oil leaks, contamination | Maintains air quality and prevents damage to downstream equipment. |

| Compressor Valves | Controls the flow of air in and out of the cylinder. | Semi-Annually | Wear and tear, leakage | Ensures efficient operation and prevents loss of pressure. |

| Belt Drive | Transfers power from the motor to the compressor. | Monthly | Slipping, fraying | Ensures reliable power transfer and smooth operation. |

| Cooling System | Maintains optimal operating temperature. | Annually | Overheating, corrosion | Prevents overheating and ensures longevity of the compressor. |

Common Compressor Issues and Preventative Measures

Compressor systems are crucial in various industries. Yet, they face common issues leading to reduced efficiency. One significant concern is overheating. Data indicates that nearly 30% of compressor failures stem from inadequate cooling. Regular checks on coolant levels can mitigate this risk.

Another prevalent problem is worn-out seals. Research shows that about 20% of malfunctioning compressors lose efficiency due to seal degradation. Maintaining integrity in seals is vital. A simple visual inspection can detect wear and tear early, saving costs on extensive repairs.

Vibration issues can also arise. Studies reveal that excessive vibrations may contribute to 25% of compressor breakdowns. Using vibration monitoring tools helps in identifying problematic areas. Taking timely action can significantly extend the lifespan of the equipment. Companies often overlook these small details. Reflections on past maintenance can inform better practices for future operations.

Benefits of Regular Compressor Maintenance for Performance and Longevity

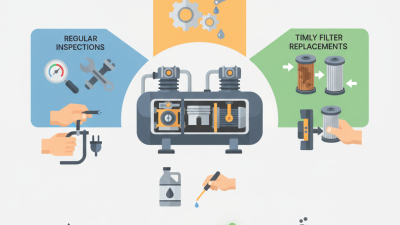

Compressor maintenance plays a crucial role in ensuring optimal performance and longevity. Regular maintenance can enhance efficiency and reduce energy costs. Problems may arise when maintenance is neglected. A simple issue like a dirty filter can lead to increased energy consumption.

One tip for maintaining your compressor is to routinely check and change air filters. Dirty filters restrict airflow and can cause overheating. Another important step is to inspect belts and hoses for wear and tear. Cracks or frays in belts could result in catastrophic failure.

It's also wise to monitor the compressor's oil levels. Low oil can lead to increased friction, reducing the machine's lifespan. Regular tuning can prevent minor issues from escalating. Many overlook these small tasks, but they are vital for smooth operation. Remember, a little attention today can save you from major headaches tomorrow.

Benefits of Regular Compressor Maintenance for Performance and Longevity

Related Posts

-

Top 10 Compressor Maintenance Tips You Can't Afford to Ignore

-

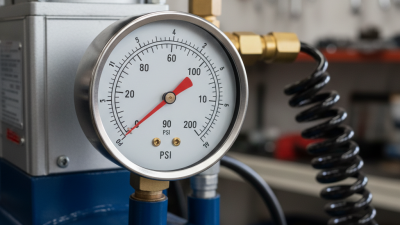

10 Essential Tips for Accurately Reading Your Air Compressor Gauge

-

How to Effectively Maintain Your Air Compressor for Optimal Performance

-

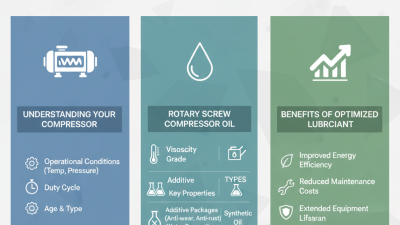

2025 Top Guide to Choosing Rotary Screw Compressor Oil for Optimal Performance

-

2025 How to Improve Air Treatment for Better Indoor Air Quality

-

Top 10 Benefits of Screw Compressor Oil for Performance?

Copyright © 2025

I&M Industrials Inc.

10 Akron Drive

Greenville SC 29605

Phone: 864-277-2450

GSA Number – GS07F0379Y