1-800-868-2450

My Account | Cart | Checkout

10 Best Practices for Optimizing Your Compressed Air Piping System

In the world of manufacturing and industrial operations, the efficiency of a compressed air piping system can greatly influence overall productivity and cost-effectiveness. According to John Smith, a renowned expert in compressed air systems, “Optimizing your compressed air piping system is not just a technical requirement; it’s a strategic move that can result in significant savings and enhanced operational efficiency.” His insights underline the fact that many organizations overlook the critical importance of properly designed and maintained piping systems, which often leads to energy losses and increased operational costs.

A well-optimized compressed air piping system can reduce energy consumption, increase system reliability, and improve air quality, ultimately leading to better performance of pneumatic tools and equipment. Engineers and facility managers must pay close attention to the layout, sizing, and maintenance of their piping systems to avoid common pitfalls that hinder performance. Implementing best practices in this regard not only enhances operational reliability but also empowers businesses to achieve greater sustainability goals and reduce their carbon footprint. As the industry evolves, staying updated with the best practices for optimizing your compressed air piping system is essential for achieving competitive advantage.

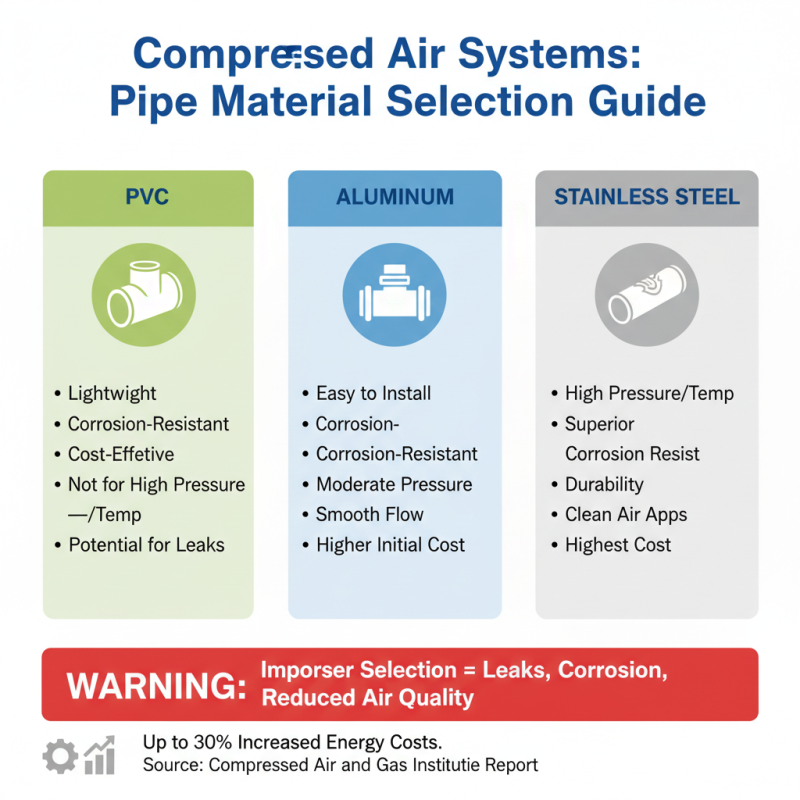

Best Practices for Selecting the Right Pipe Material for Air Systems

Selecting the right pipe material for compressed air systems is crucial for optimizing performance, longevity, and energy efficiency. Various materials such as PVC, aluminum, and stainless steel are commonly used, each presenting distinct benefits and drawbacks. According to a report by the Compressed Air and Gas Institute, improper material selection can lead to leaks, corrosion, and reduced air quality, all of which may increase energy costs by up to 30%. For instance, while PVC is lightweight and resistant to corrosion, it may not handle the pressure fluctuations inherent in industrial environments as effectively as metals like aluminum or stainless steel.

When considering pipe material, it's also essential to evaluate compatibility with the specific application and the compressed air's quality requirements. Metals generally offer higher durability and resistance to impacts and temperature variations, crucial in environments where extreme conditions might arise. A study published by the International Journal of Compressed Air Systems indicates that using galvanized steel pipes can reduce energy loss by approximately 5% compared to less durable options. Therefore, investing in higher-quality materials may yield significant long-term savings through enhanced efficiency and reduced maintenance needs, ultimately leading to a more reliable airflow system.

Calculating Optimal Pipe Diameter to Minimize Pressure Drop in Air Systems

When optimizing a compressed air piping system, one critical element is the calculation of the optimal pipe diameter. Choosing the right diameter minimizes pressure drop, which is essential for maintaining system efficiency and performance. A proper balance must be struck between ensuring that the pipe is large enough to accommodate the required air flow while also avoiding unnecessarily high costs associated with larger pipes. As air flows through a pipe, friction and turbulence can cause a drop in pressure, leading to reduced performance in downstream equipment.

To effectively calculate the optimal pipe diameter, engineers must consider factors such as the flow rate, the type of air usage, and the total length of the piping run. Utilizing the ideal gas law and fluid dynamics equations, one can estimate the required diameter that will allow for the desired flow rate with minimal pressure loss. Additionally, proper sizing accounts for the specific characteristics of the system, such as the number of bends and fittings, which can further contribute to pressure drop. By paying careful attention to these factors, businesses can ensure they design an air system that operates efficiently and effectively, ultimately reducing energy costs and improving overall productivity.

Utilizing Proper Fittings and Joint Configurations for Maximum Efficiency

When it comes to optimizing a compressed air piping system, utilizing proper fittings and joint configurations plays a crucial role in maximizing efficiency. According to the Compressed Air and Gas Institute (CAGI), approximately 30% of compressed air systems operate with leaks that can significantly diminish system performance. Properly selected fittings and connections can mitigate these losses by ensuring minimal pressure drops and reducing turbulence within the piping network. Using fittings designed for specific applications can enhance airflow and contribute to the system’s overall effectiveness.

Moreover, joint configurations significantly influence the energy consumption of a compressed air system. Research indicates that improper joint design can lead to a 10-15% loss in efficiency due to increased friction and pressure drop. Therefore, utilizing configurations such as smooth-radius elbows rather than sharp 90-degree bends can reduce turbulence and promote more efficient airflow. Additionally, ensuring that connections are leak-free and properly aligned reduces the workload on the compressor, further contributing to energy savings. According to a study by the U.S. Department of Energy, addressing these factors can lead to reduced operating costs by up to 20% while enhancing system reliability.

Implementing Regular Maintenance Schedules to Enhance System Longevity

Implementing regular maintenance schedules is essential for optimizing your compressed air piping system and enhancing its longevity. Consistent upkeep can prevent unexpected downtime and extend the life of the equipment. It is important to develop a maintenance timeline that includes routine checks, cleaning, and necessary repairs. This proactive approach not only maximizes efficiency but also ensures that potential issues are identified and addressed before they escalate into costly repairs.

Tips for maintaining your compressed air piping system include conducting regular inspections to look for leaks or signs of wear. Leaks can lead to significant energy losses, impacting overall efficiency. Additionally, consider scheduling pressure tests to confirm that your system is performing at optimal levels. Keeping air filters clean is also vital; dirty filters can reduce airflow and lead to increased energy consumption. Regularly updating your maintenance logs will help you track any anomalies and maintain a history of the system's performance, which can guide future improvements.

Another effective tip is to engage your team in training sessions focused on the importance of compressed air system maintenance. Equip them with the knowledge to recognize issues and take prompt action. Encouraging a culture of accountability around maintenance can significantly contribute to system reliability and longevity. By fostering a proactive maintenance environment, not only will you enhance the performance of your piping system, but you will also empower your employees to take an active role in ensuring operational excellence.

Monitoring Air Quality and Pressure to Ensure System Performance Reliability

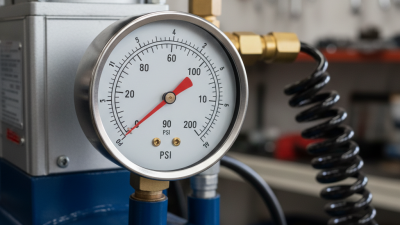

Ensuring the reliability and efficiency of a compressed air piping system hinges on robust monitoring of air quality and pressure. Contaminants such as moisture, oil, and dirt can significantly impact the performance of air tools and machinery. Regularly assessing the air quality not only prolongs equipment life but also enhances the quality of the end products. Utilizing filters and separators in conjunction with real-time monitoring sensors can provide insight into potential contaminant levels, aiding in maintaining a clean air supply.

In addition to air quality, monitoring pressure throughout the piping system is crucial. Pressure fluctuations can indicate leaks, blockages, or inadequate supply, leading to inefficient operations and increased energy costs. Installing pressure gauges at strategic points within the system allows for continuous observation and timely adjustments. By establishing a routine for pressure checks and maintaining the integrity of the piping infrastructure, businesses can optimize their compressed air consumption, thus ensuring a reliable system performance.

Related Posts

-

How to Easily Find Affordable Compressor Repair Services in 2025

-

The Future of Industrial Air Compressor Technology Innovations to Watch

-

Unlocking the Power of High Pressure Air Compressors for Home and Industry

-

10 Essential Tips for Accurately Reading Your Air Compressor Gauge

-

Top 10 Industrial Air Solutions to Optimize Your Facility's Efficiency

-

Maximizing Efficiency with Industrial Air Compressor Rental Services for Your Business Needs

Copyright © 2025

I&M Industrials Inc.

10 Akron Drive

Greenville SC 29605

Phone: 864-277-2450

GSA Number – GS07F0379Y