1-800-868-2450

My Account | Cart | Checkout

Top 10 Best Gardner Denver Air Compressors for Your Workshop Needs

When it comes to setting up a workshop, having the right equipment is crucial, and one essential tool that often takes the spotlight is the air compressor. Among the various options available in the market, the Gardner Denver air compressor stands out for its reliability and performance, making it a top choice for both hobbyists and professionals alike. With a rich history of engineering excellence, Gardner Denver has engineered a range of air compressors that cater to diverse workshop needs, ensuring that tasks can be carried out efficiently and effectively.

In this article, we will explore the top 10 best Gardner Denver air compressors, allowing you to make an informed decision on which model will best suit your workshop environment. Whether you are engaged in woodworking, automotive repair, or any other pneumatic application, there is a Gardner Denver air compressor designed to provide the power and versatility you require. We will delve into the specifications, features, and benefits of each model, helping you to select the perfect compressor that meets your demands while enhancing your overall workshop productivity.

Top Features to Consider When Choosing Gardner Denver Air Compressors

When selecting the ideal air compressor for your workshop, there are several key features to consider that can significantly impact performance and efficiency. One critical aspect is the compressor's horsepower (HP) rating, which directly correlates with its ability to handle demanding tasks. According to industry data, a compressor with at least 5 HP is generally recommended for workshops that require heavy-duty applications, ensuring sufficient airflow and pressure for tools such as impact wrenches and spray guns.

Another important feature is the tank size, which affects the compressor's ability to deliver a continuous and stable air supply. Reports indicate that a larger tank, typically above 60 gallons, can maintain air pressure during extended use, reducing the frequency of compressor cycling. This not only enhances productivity but also prolongs the lifespan of the equipment by minimizing wear and tear. Additionally, the choice of oil-lubricated versus oil-free compressors should be considered based on maintenance preferences and operating noise levels; oil-lubricated models are known for durability but require more upkeep compared to their oil-free counterparts.

Lastly, the portability of the air compressor should not be overlooked, especially for those who may need to move their equipment frequently. A lightweight model with wheels can offer significant advantages in terms of versatility within a workshop environment. As highlighted in various industry analyses, user convenience and mobility are essential factors that contribute to overall operational efficiency, helping ensure that your tools are always ready to perform when needed.

Comparison of Rotary Screw vs. Reciprocating Air Compressors by Gardner Denver

When selecting an air compressor for workshop needs, understanding the differences between rotary screw and reciprocating designs is essential. Rotary screw compressors employ two rotors to compress air continuously, resulting in a steady supply of air pressure. Their efficiency shines in applications requiring high volumes of air over extended periods. According to industry reports, rotary screw compressors can typically operate at an efficiency of 80-90%, and they often have longer lifespans due to fewer moving parts, making them ideal for heavy-duty tasks in workshops.

On the other hand, reciprocating air compressors function by using pistons to compress air in a cyclical motion. These compressors are generally less costly to purchase and maintain, making them suitable for small-scale or intermittent use. While reciprocating designs can achieve higher pressures (commonly up to 175 psi), their operational cost may be higher due to energy inefficiencies. Reports indicate that these compressors can consume 15-30% more energy compared to rotary screw types, particularly when continuously running, which may impact overall workshop operational costs. Choosing the right compressor involves weighing the immediate budget against long-term efficiency and energy consumption, crucial factors for any serious workshop owner.

Efficiency Ratings: Understanding CFM (Cubic Feet per Minute) in Air Tools

Understanding CFM, or Cubic Feet per Minute, is essential when selecting an air compressor that meets your workshop needs. This measurement indicates the volume of air the compressor can deliver in one minute, which is critical for powering various air tools. For example, a nail gun may require a certain CFM at a specified pressure to function optimally. Therefore, it's important to match the CFM rating of the compressor with the requirements of the tools you intend to use.

When selecting an air compressor, consider not just the CFM rating but also the pressure settings. Different tools will operate more efficiently at varying PSI (Pounds per Square Inch). Balancing these two factors ensures that your compressor will provide the necessary power for your projects without causing delays or performance issues.

Tip: Always account for additional CFM requirements if you're using multiple tools simultaneously. A good rule of thumb is to add about 30% to the total CFM needed for peak performance. This will prevent your compressor from running continuously, which can lead to overheating and decreased lifespan. Additionally, researching the specific CFM requirements for your air tools can help make a well-informed purchase decision.

Top 10 Best Air Compressors for Your Workshop Needs

This chart presents the efficiency ratings of different air compressors based on their CFM (Cubic Feet per Minute) output, which is crucial for air tools performance.

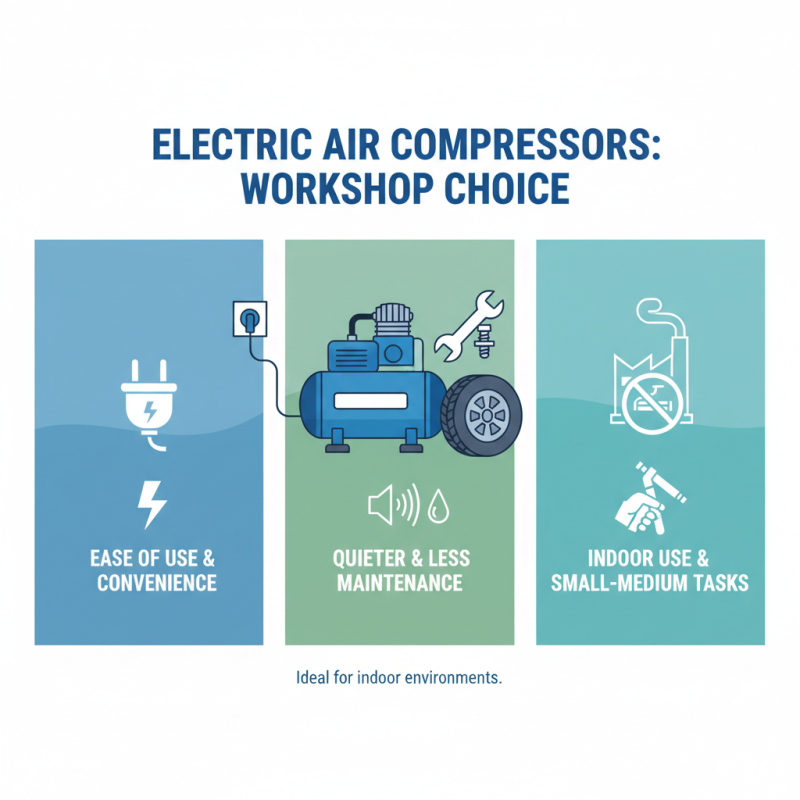

Electric vs. Gas-Powered Gardner Denver Compressors for Workshop Applications

When choosing the right compressor for your workshop, understanding the differences between electric and gas-powered models is crucial. Electric air compressors are often favored for their convenience and ease of use. They generally operate quietly and require less maintenance compared to their gas counterparts. Electric models can be plugged into standard outlets, making them an ideal choice for indoor environments where noise and emissions are a concern. They are well-suited for tasks like inflating tires or powering pneumatic tools for small to medium tasks.

On the other hand, gas-powered compressors offer significant advantages in terms of mobility and power output. These models are equipped with engines that enable them to operate in areas without access to electricity, making them a perfect choice for outdoor projects and construction sites. Gas-powered compressors tend to deliver higher PSI levels, making them capable of handling heavier-duty applications. However, they produce noise and exhaust fumes, which can limit their use in enclosed spaces. Ultimately, the choice between electric and gas-powered compressors will depend on the specific requirements of your workshop tasks, including the need for mobility, power, and the working environment.

Maintenance Requirements and Lifespan of Gardner Denver Air Compressors

When it comes to air compressors, regular maintenance is crucial for ensuring longevity and optimal performance in your workshop. Essential maintenance tasks include regularly checking and changing the oil, cleaning or replacing air filters, and ensuring proper lubrication of moving parts. These proactive measures not only enhance efficiency but also significantly extend the lifespan of the compressor. Ignoring these maintenance requirements can lead to increased wear and tear, ultimately resulting in costly repairs or replacement.

The lifespan of an air compressor is largely influenced by its maintenance practices and usage conditions. Typically, well-maintained compressors can last anywhere from 10 to 15 years, or even longer with diligent care. To maximize durability, operators should adhere to manufacturer guidelines and conduct routine inspections. Monitoring components such as hoses, belts, and valves for signs of damage or wear is also essential. By investing time in regular upkeep, users can ensure that their air compressors remain reliable tools in their workshops for years to come.

Related Posts

-

Maximizing Efficiency: How Industrial Air Compressors Transform Manufacturing Processes

-

The Future of Industrial Air Compressor Technology Innovations to Watch

-

The Ultimate Guide to Choosing the Right Compressed Air Dryer for Your Industrial Needs

-

Top 10 Compressor Maintenance Tips You Can't Afford to Ignore

-

Maximize Efficiency: The Surge in Industrial Air Compressor Rental Demand for Sustainable Practices in Manufacturing

-

2025 How to Improve Air Treatment for Better Indoor Air Quality

Copyright © 2025

I&M Industrials Inc.

10 Akron Drive

Greenville SC 29605

Phone: 864-277-2450

GSA Number – GS07F0379Y