1-800-868-2450

My Account | Cart | Checkout

Top 10 Benefits of Using an Oil Free Compressor for Your Business

In today's competitive business landscape, the quest for efficiency and sustainability has led many companies to explore innovative technologies. One such advancement is the oil free compressor, which offers numerous advantages over traditional alternatives. Experts in the field, such as Dr. Emily Johnson, a leading authority in compressed air systems, emphasize the importance of this technology. She states, "Switching to an oil free compressor not only enhances operational efficiency but also significantly reduces environmental impact."

The benefits of using oil free compressors extend beyond mere functionality; they play a crucial role in maintaining product quality while simultaneously lowering maintenance costs. Industries such as pharmaceuticals, food processing, and electronics increasingly rely on these systems to ensure the purity of their output. With growing emphasis on sustainability and reduced carbon footprints, the adoption of an oil free compressor represents a strategic move for forward-thinking businesses.

As we delve into the top ten benefits of integrating oil free compressors into business operations, it becomes evident that this technology is not just a trend but a vital component for companies aiming to thrive in a sustainable future. Whether it's reduced energy consumption or enhanced reliability, understanding these advantages is key to making informed decisions that foster both growth and environmental responsibility.

Benefits of Reduced Maintenance with Oil Free Compressors

Oil-free compressors offer significant advantages for businesses, particularly in terms of reduced maintenance needs. Traditional oil-lubricated compressors often require regular oil changes, extensive cleaning, and periodic monitoring, which can lead to increased downtime and operational costs. According to a report by the Compressed Air and Gas Institute, oil-free compressors can reduce maintenance costs by up to 30%, allowing businesses to reallocate resources towards more productive activities.

In addition to lower maintenance expenses, oil-free compressors enhance reliability and product quality. The absence of lubricating oil minimizes the risk of contamination in the compressed air supply, an essential factor for industries such as food and beverage, pharmaceuticals, and electronics. A study by the International Journal of Compressed Air Technology noted that companies using oil-free systems experienced a reduction in product defects attributable to compressed air quality issues by approximately 40%. This improved standard not only boosts operational efficiency but also safeguards a company's reputation by consistently delivering high-quality products.

Ultimately, the transition to oil-free compressors aligns with the growing demand for sustainable and cost-effective solutions in various sectors. With lower maintenance needs and superior air quality, businesses can expect a significant return on investment, underscoring the long-term benefits of adopting this technology.

Top 10 Benefits of Using an Oil Free Compressor for Your Business - Benefits of Reduced Maintenance with Oil Free Compressors

| Benefit | Description | Impact on Business |

|---|---|---|

| Reduced Oil Maintenance | Eliminates the need for regular oil changes and associated costs. | Lower maintenance costs and downtime. |

| Cleaner Operations | No oil contamination in the compressed air produced. | Improved product quality and reduced risk of contamination. |

| Energy Efficiency | More efficient operation leading to lower energy costs. | Reduced operating costs and environmental impact. |

| Lower Operating Temperatures | Runs cooler due to less heat generated from oil friction. | Increases equipment lifespan and reliability. |

| Compact Design | Tends to be smaller and lighter than oil-lubricated compressors. | Easier installation and space savings in facilities. |

| Environmentally Friendly | No oil disposal issues or environmental hazards. | Enhanced corporate sustainability and compliance. |

| Noise Reduction | Generally operates more quietly than oil compressors. | Improved work environment and compliance with noise regulations. |

| Better Air Quality | Reduced risk of air contamination benefits workplace safety. | Healthier employees and reduced liabilities. |

| Versatility | Suitable for a variety of applications and industries. | Wider application range and more business opportunities. |

| Increased Productivity | Less downtime and maintenance means more operating time. | Higher output and profitability for businesses. |

Impact on Environmental Sustainability from Oil Free Compressors

The adoption of oil-free compressors plays a crucial role in promoting environmental sustainability for businesses. Unlike traditional compressors, which rely on oil for lubrication and operation, oil-free models eliminate the risk of oil contamination in the air supply. This significantly reduces the environmental impact, as there are no harmful residues that can pollute the atmosphere or contribute to soil and water contamination. By using oil-free compressors, companies not only comply with stricter regulations regarding emissions and waste but also demonstrate their commitment to responsible environmental practices.

Moreover, oil-free compressors contribute to energy efficiency, as they are designed to operate at optimal performance without the additional energy requirements associated with oil filtration systems. This efficiency translates into lower energy consumption, which not only reduces operational costs but also decreases the overall carbon footprint of a business. By investing in technologies that prioritize sustainability, companies can enhance their corporate image and appeal to environmentally conscious consumers, ultimately benefiting both the planet and their bottom line.

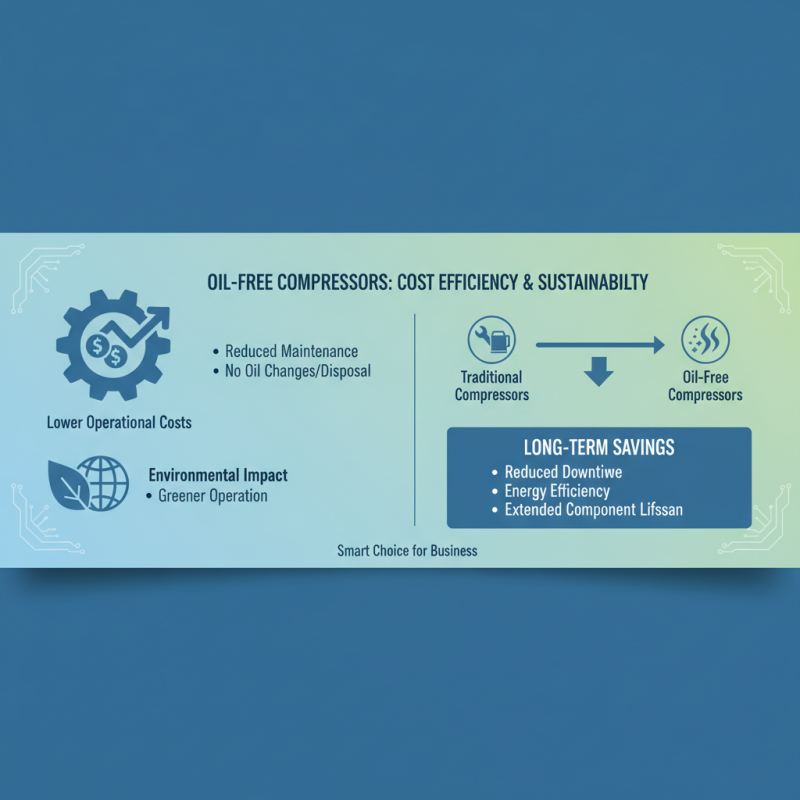

Cost Efficiency of Oil Free Compressors for Long-Term Business Savings

Oil-free compressors offer substantial cost efficiency, making them an appealing choice for businesses seeking long-term savings. Unlike traditional oil-lubricated compressors that require regular maintenance and replacement of oil, oil-free compressors are designed with less wear and tear on components. This results in lower operational costs over time, as businesses can save on maintenance fees and downtime associated with oil changes and servicing. The elimination of oil not only simplifies maintenance but also reduces the environmental impact of disposing of used oil, contributing to a more sustainable operational approach.

Moreover, oil-free compressors tend to have a longer lifespan due to their design, further enhancing cost efficiency. With fewer moving parts that can accumulate contaminants, these compressors operate more smoothly and reliably. This reliability translates to fewer unexpected repairs and interruptions, allowing businesses to maintain productivity levels consistently. Additionally, many oil-free compressors come with energy-efficient technologies, reducing energy consumption and utility costs. This combination of durability, reduced maintenance, and energy efficiency makes oil-free compressors an investment that yields significant savings for businesses in the long run.

Improved Air Quality and Product Quality with Oil Free Technology

Oil-free compressors have emerged as a game-changer in various industries, especially in terms of improved air quality and product quality. Traditional compressors often rely on lubrication oil, which can lead to oil contamination in the compressed air. This poses risks, particularly in sectors such as food processing, pharmaceuticals, and electronics manufacturing, where air purity is critical. According to a report by the International Compressor Manufacturers Association, oil-free technology can reduce the risk of contamination by 99%, ensuring cleaner air and safer operations.

Moreover, the use of oil-free compressors can greatly enhance the quality of end products. In a study published by the Compressed Air & Gas Institute, it was found that companies implementing oil-free systems reported a 30% reduction in product defects related to air quality issues. For instance, in the food and beverage industry, oil-free air is vital for processes like packaging and bottling, where even a slight oil presence can spoil product integrity. By investing in oil-free compressors, businesses not only improve their operational efficiency but also safeguard the quality of their products, leading to increased customer satisfaction and reduced waste.

The economic implications of switching to oil-free technology are equally compelling. A report from the Energy Efficiency Council indicates that facilities using oil-free compressors experience lower maintenance costs—up to 50% less over the lifespan of the equipment—due to the elimination of oil management and replacement. Additionally, the energy efficiency of oil-free systems can lead to an average savings of 15% on energy bills, making them not only a cleaner but also a more cost-effective choice for modern businesses.

Versatility and Application in Various Industries for Oil Free Compressors

Oil-free compressors have gained prominence across various industries due to their versatility and operational efficiency. According to a report by the International Journal of Engineering Research & Technology, these compressors can reduce operational costs by up to 30% when compared to traditional oil-lubricated models. The elimination of oil significantly decreases maintenance requirements and reduces the risk of contamination in sensitive applications, such as food processing and pharmaceuticals, where oil traces could compromise product integrity.

In the automotive sector, oil-free compressors are increasingly used for pneumatic tools and tire inflation, contributing to efficiency and improved safety. A survey conducted by the Compressor & Blower Manufacturers Association indicates that over 60% of automotive facilities have transitioned to oil-free systems to enhance air quality and streamline operations. Furthermore, the electronics industry benefits from oil-free compressors in their manufacturing processes, as they ensure a pristine environment that's critical for sensitive electronic components.

**Tip:** When selecting an oil-free compressor, consider the specific needs of your operations. Ensure that the compressor's flow rate and pressure match your requirements to maximize efficiency.

Another crucial factor is energy consumption. Many oil-free compressors are designed to be energy-efficient, potentially leading to significant cost savings in long-term energy bills.

**Tip:** Regular maintenance checks and monitoring performance can help identify any inefficiencies early, ensuring your system operates at peak performance.

Top 10 Benefits of Using an Oil Free Compressor for Your Business

Related Posts

-

Top 10 Best Gardner Denver Air Compressors for Your Workshop Needs

-

Why Pressure Gauges are Essential for Accurate Measurements in Various Industries

-

Top 10 Air Solutions for Optimal Indoor Air Quality in 2023

-

Maximize Efficiency: The Surge in Industrial Air Compressor Rental Demand for Sustainable Practices in Manufacturing

-

2025 How to Choose the Best Air Compressor Oil for Optimal Performance

-

Why Process Equipment is Essential for Efficient Industrial Operations

Copyright © 2025

I&M Industrials Inc.

10 Akron Drive

Greenville SC 29605

Phone: 864-277-2450

GSA Number – GS07F0379Y