1-800-868-2450

My Account | Cart | Checkout

Top 10 Benefits of Screw Compressor Oil for Performance?

Screw compressor oil plays a crucial role in the efficiency and longevity of screw compressors. It serves not only as a lubricant but also as a vital component that enhances performance. The right screw compressor oil can improve your compressor's efficiency, leading to lower operational costs.

Using high-quality screw compressor oil ensures optimal performance. It reduces friction and wear, extending the life of your equipment. This benefits not just the machine but also the overall productivity of your operations. You might notice fewer breakdowns and less downtime when using the right oil.

However, choosing the correct screw compressor oil can be challenging. Variations in formulations can lead to confusion. It's essential to analyze specific needs before making a choice. Proper maintenance and oil selection can sometimes reflect a larger understanding of the equipment's requirements. In the end, it's about finding the right balance between performance and reliability.

Benefits of Screw Compressor Oil on Energy Efficiency Optimization

Screw compressor oil plays a crucial role in energy efficiency optimization. According to a recent industry report, using the right oil can enhance compressor efficiency by up to 10%. This improvement translates to significant energy savings over time, especially in large industrial settings. Compressors often function continuously, so small efficiency gains can lead to substantial cost reductions.

Proper lubrication minimizes friction and wear. A well-lubricated screw compressor operates smoother, requiring less energy to maintain the desired performance. Studies indicate that inadequate lubrication can increase energy consumption by 15% or more. Choosing high-quality screw compressor oil helps maintain optimal viscosity, ensuring the compressor runs efficiently under varying conditions.

Some facilities overlook oil quality, leading to inefficiencies. Regular monitoring and analysis of oil condition can prevent unexpected breakdowns. Neglecting this aspect may result in higher operational costs. Companies should consider implementing a scheduled maintenance routine to monitor oil performance. By focusing on lubrication, businesses can enhance not only their compressor's lifespan but also their energy management strategies.

Impact of Screw Compressor Oil on Lubrication Stability and Lifespan

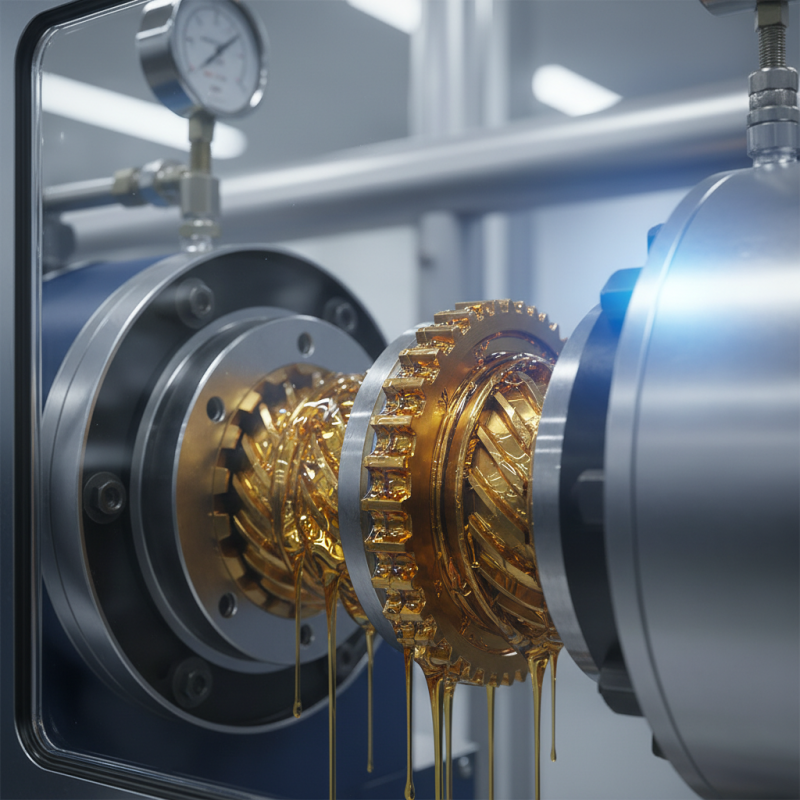

Screw compressor oil plays a vital role in ensuring stable lubrication and extending the lifespan of the compressor. High-quality oil reduces friction between moving parts. This is crucial because friction generates heat, which can lead to wear over time. Effective lubrication ensures that components work smoothly, reducing the risk of breakdowns.

Using the right viscosity is essential. If the oil is too thin, it won't provide adequate protection. Conversely, oil that's too thick can impede operation. Regularly checking and changing the oil can significantly improve performance and longevity.

Tip: Always monitor oil levels. Low oil levels can lead to increased wear and tear. Keep an eye out for unusual noises. This may indicate that the oil is breaking down.

Unconventional oils may sometimes offer benefits, but they can be unpredictable. Be cautious when experimenting. Prioritizing stability is key for long-term operation. Regular maintenance, including oil analysis, can offer insights into potential issues. Consistent monitoring is your best defense against costly repairs.

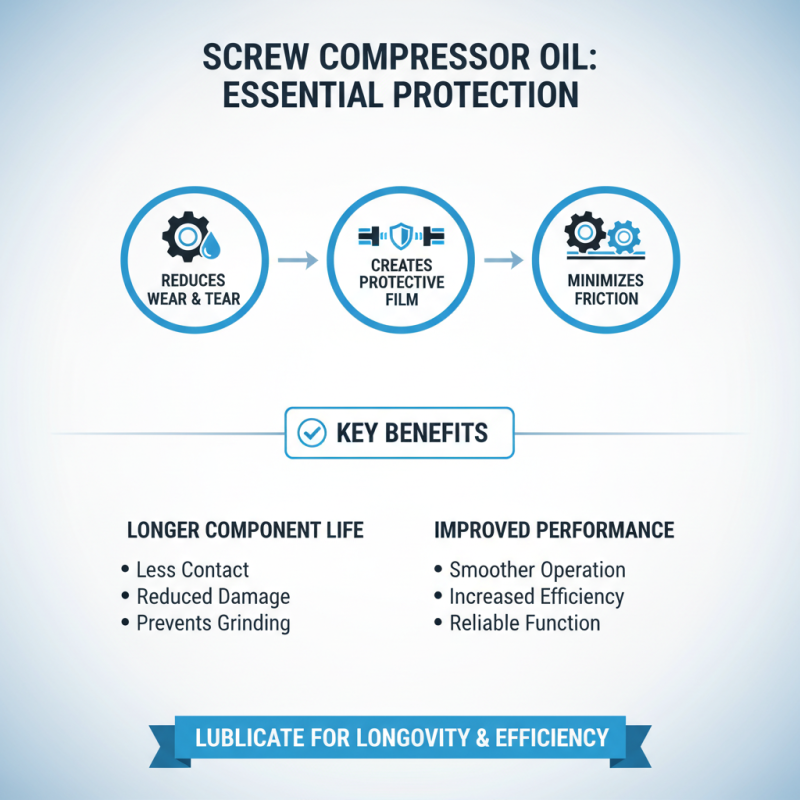

Role of Screw Compressor Oil in Reducing Wear and Tear on Components

Screw compressor oil plays a vital role in reducing wear and tear on components. It creates a protective film that minimizes friction. This film reduces the contact between moving parts. As a result, components experience less damage over time. Proper lubrication keeps parts from grinding against each other.

Moreover, high-quality oil can absorb heat effectively. Excessive heat can lead to component failure. By keeping temperatures in check, oil extends the life of the compressor. Often, users overlook the significance of regular oil changes. Stale oil can lose its properties. This negligence may lead to increased wear and overheating issues.

Another aspect to consider is contamination. Dirt and particles can enter the system, causing abrasive damage. Good screw compressor oil has additives that help combat these contaminants. However, the effectiveness can diminish over time. Regular monitoring is essential to keep the system running smoothly. Utilizing the right maintenance practices can improve overall performance.

Evaluation of Screw Compressor Oil's Performance Under Extreme Conditions

Screw compressors operate under extreme conditions. Their longevity heavily relies on the quality of compressor oil used. A study from the International Journal of Refrigeration highlights that premium screw compressor oils can enhance efficiency by up to 15%. High-performance oils reduce wear and tear, which is vital at high temperatures.

The operating environment can stress lubricants significantly. For instance, when temperatures exceed 100°C, standard oils may break down. This leads to increased friction and wear. Alternative formulations, however, can maintain stability. Data from the American Society of Heating, Refrigerating and Air-Conditioning Engineers indicates that specific synthetic oils can withstand temperatures up to 150°C without degrading.

Fouling and contamination are persistent issues. Under harsh conditions, oil cleanliness diminishes, impacting compressor reliability. Regular monitoring and replacement are crucial. A report from the Compressors and Vacuum Pumps Association reveals that inadequate lubrication can decrease performance by over 30%. These statistics show the necessity of using high-quality oils and recognizing their limitations.

Cost-Benefit Analysis of Using High-Quality Screw Compressor Oil

Investing in high-quality screw compressor oil can seem costly at first. However, a closer look reveals its cost-saving potential over time. Using premium oil improves the overall efficiency of the compressor. An efficient compressor operates at a lower energy cost, which can lead to significant savings in utility bills.

Maintenance is another critical area where high-quality oil makes a difference. Better lubrication reduces wear and tear on components. This results in fewer service calls and prolonged equipment lifespan. It’s worth contemplating how much downtime can affect your operations. The initial splash of spending on quality oil may prevent larger repair costs down the line.

It is essential to recognize not all oils are created equal. Some cheaper options may provide immediate savings but can lead to larger expenses later. A false economy emerges when you prioritize upfront costs over long-term performance. Therefore, investing in high-quality screw compressor oil is wise.

Top 10 Benefits of Screw Compressor Oil for Performance

Related Posts

-

Top 10 Air Compressor Models for Efficient Performance and Reliability in 2023

-

Top 10 Industrial Air Solutions to Optimize Your Facility's Efficiency

-

Top 10 Industrial Compressors of 2023: Performance, Efficiency, and Reliability Insights

-

How to Choose the Best Air Pressure Gauge for Your Needs in 2025

-

Maximize Efficiency: The Surge in Industrial Air Compressor Rental Demand for Sustainable Practices in Manufacturing

-

Top 10 Compressor Maintenance Tips You Can't Afford to Ignore

Copyright © 2025

I&M Industrials Inc.

10 Akron Drive

Greenville SC 29605

Phone: 864-277-2450

GSA Number – GS07F0379Y