1-800-868-2450

My Account | Cart | Checkout

2026 Top Air Compressor Industrial Innovations and Trends?

In the rapidly evolving air compressor industrial sector, staying ahead hinges on innovation. Industry expert Dr. Emily Chen, a recognized authority in air compressor technology, states, "Innovation is the backbone of the air compressor industrial market." Her insight reflects the core of the upcoming trends expected in 2026.

The landscape is shifting. Manufacturers are investing in smart technology and energy efficiency. This creates a more sustainable future. However, challenges persist. Not all innovations are practical or cost-effective. It’s essential to distinguish between hype and real advancements. The push towards greener solutions is crucial, but technical feasibility must also be considered.

Amid these changes, companies must embrace a culture of continuous improvement. The goal is not just to lead but to adapt. Old models may falter, and new needs arise. Keeping pace with the demands of Industry 4.0 will require both bold ideas and careful reflection. The journey of the air compressor industrial sector is both exciting and uncertain.

2026 Trends in Air Compressor Technologies and Innovations

In 2026, air compressor technology is set to evolve significantly. Lightweight materials are becoming common, enhancing portability. This trend allows for mobile solutions in various industries. Additionally, energy efficiency remains a focal point. Innovators are exploring alternatives to traditional energy sources. Solar-powered compressors are gaining attention, but they still face challenges in consistent output.

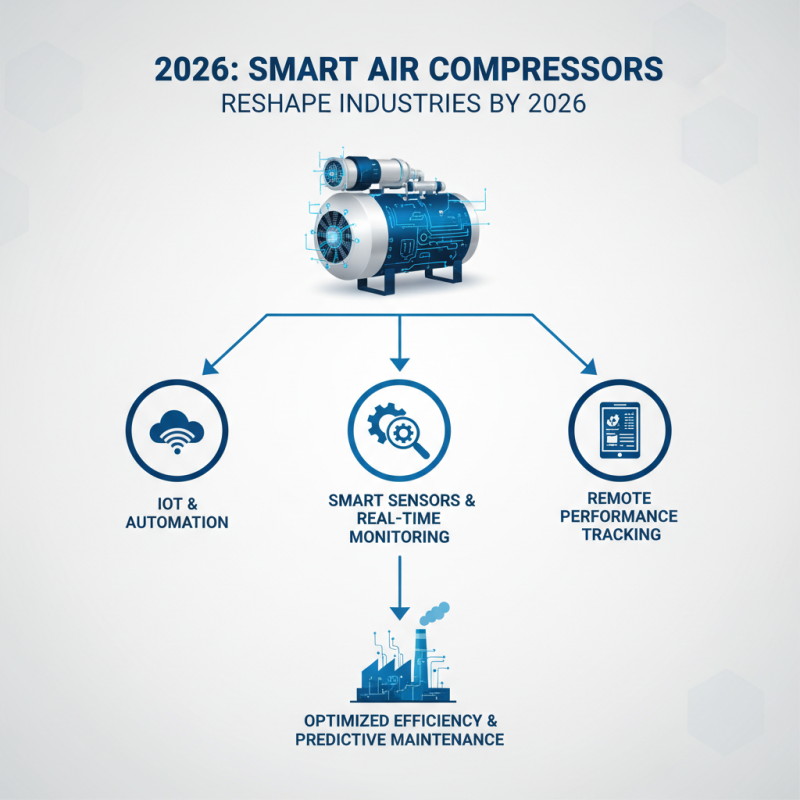

Smart technology integration is another compelling trend. Many compressors now feature IoT capabilities. This allows for real-time monitoring and predictive maintenance. Companies have started to embrace this approach. However, some struggle with data overload. Users may find it difficult to interpret all the information.

Moreover, environmental sustainability plays a critical role in innovation. Many air compressors now focus on reducing carbon footprints. Manufacturers are investing in greener technologies. Yet, implementation can be slow. Resistance to change is a common hurdle. Addressing these issues is crucial for future advancements.

2026 Trends in Air Compressor Technologies and Innovations

Key Industry Innovations Reshaping Air Compressors in 2026

The air compressor industry is witnessing dynamic changes in 2026. Innovations are not just about efficiency; they also focus on sustainability. A recent report indicates that energy-efficient designs can reduce operational costs by up to 30%. This shift is crucial as companies strive to lower their carbon footprints while maintaining performance.

One noteworthy trend is the integration of IoT technology. Smart air compressors are becoming standard in many facilities. They enable real-time monitoring, enhancing predictive maintenance strategies. Studies show that predictive maintenance can cut downtime by nearly 40%. However, adapting to these technologies often presents challenges. Not all businesses are ready for such digital transformation.

Additionally, there’s a rising emphasis on compact and portable models. These machines often weigh less than traditional units, yet deliver substantial power. Although convenient, their durability remains a concern. Many users report issues with longevity under constant use. Understanding these trade-offs is essential for making informed equipment choices in the evolving market.

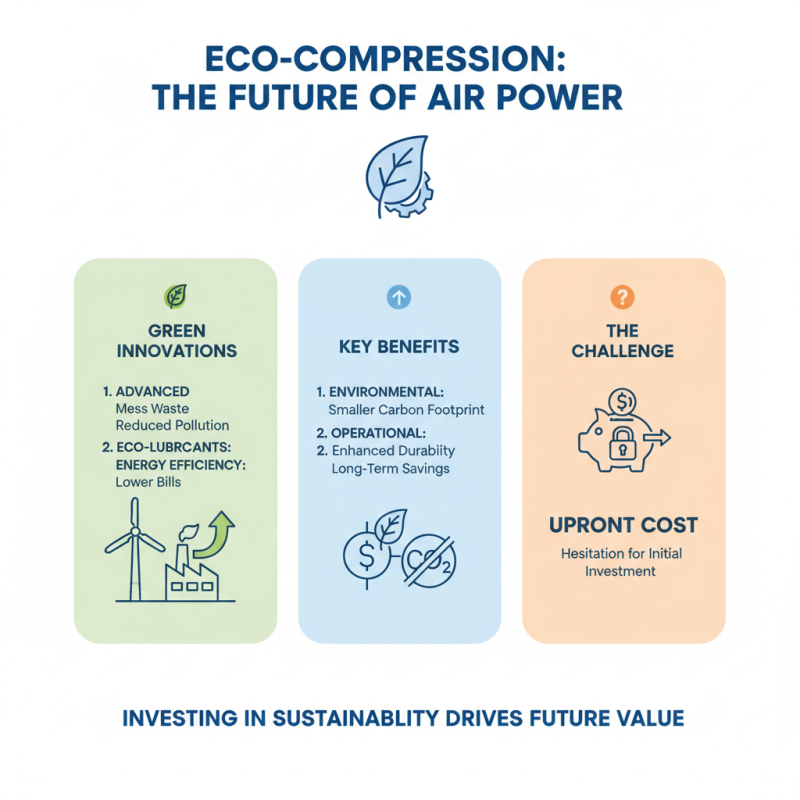

Sustainability and Energy Efficiency in Modern Air Compressors

Sustainability and energy efficiency have become crucial in the air compressor industry. Modern designs incorporate advanced materials, reducing waste. Using eco-friendly lubricants is now a common trend. This helps decrease the environmental impact. However, the challenge remains in the cost. Some companies hesitate to invest upfront. They worry about immediate financial returns.

Regular maintenance is key to energy efficiency. Neglected compressors consume more energy. Poor maintenance can lead to leaks. These leaks waste both energy and resources. A reliable monitoring system can help. It ensures optimal performance and identifies inefficiencies. Still, not all companies prioritize this investment. Many focus solely on initial purchase costs rather than long-term benefits.

Energy-efficient compressors can lead to significant savings. They consume less electricity while delivering the same power. This shift is not just about saving money; it’s about preserving the environment. Yet, the spectrum of available options can be overwhelming. Choosing the right technology requires research and careful evaluation. Companies often struggle to make informed decisions.

Smart Air Compressors: The Role of IoT and Automation in 2026

In 2026, smart air compressors will reshape industries. These devices leverage the Internet of Things (IoT) and automation. Integration with smart sensors will allow for real-time monitoring. Businesses can track performance, efficiency, and maintenance needs from anywhere.

Automation will lead to predictive maintenance. This means reduced downtime and operational costs. However, reliance on technology may create vulnerabilities. System failures could disrupt production. It highlights the importance of backup systems and manual checks.

Tips: Regular training for staff is essential. Familiarity with new tech ensures smooth operations. Always monitor data trends closely. Adjust your strategy based on performance insights. Being proactive can prevent larger issues down the line. Embrace change but remain cautious. Balancing innovation with traditional methods may be vital.

Future Challenges and Opportunities in Air Compressor Manufacturing

The air compressor industry faces new challenges as it moves toward 2026. Environmental regulations are tightening. Manufacturers must adapt to these changes. Energy efficiency is becoming a key focus. Innovations in design can lead to better performance while reducing emissions. This shift is crucial for complying with regulations and meeting market demands.

Technological advancements provide both challenges and opportunities. Smart technologies are paving the way for improved monitoring. Advanced sensors can enhance functionality but may increase costs. Balancing innovation with affordability is a complex task. The industry must also address the skills gap. Many workers need training to keep pace with new technologies.

Embracing these challenges requires a proactive mindset. Collaboration among stakeholders will foster better solutions. Manufacturers must consider sustainability as a core principle. Investing in research and development is essential for long-term success. The future holds significant potential for those willing to innovate. However, complacency may hinder progress. Adapting to change is not just an option; it's a necessity.

2026 Top Air Compressor Industrial Innovations and Trends

| Innovation/Trend | Description | Expected Impact | Challenges | Opportunities |

|---|---|---|---|---|

| Smart Air Compressors | Integration of IoT technology for real-time data monitoring | Enhanced operational efficiency and predictive maintenance | High initial investment and cybersecurity concerns | Growing demand for automation in industrial processes |

| Energy-Efficient Models | Design improvements focus on energy savings | Reduction in operational costs and carbon footprint | Compliance with new energy regulations | Increasing regulatory support for green technologies |

| Noise Reduction Technologies | Advanced soundproofing solutions in design | Improved workplace safety and comfort | Higher production costs for quieter designs | Growing awareness of workplace health and safety |

| Mobile Air Compressors | Increases flexibility and convenience on job sites | Accessibility to remote locations without power supply | Limited capacity compared to stationary models | Rising demand from construction and maintenance industries |

| Modular Systems | Customization options for specific industrial needs | Enhanced performance tailored to distinct applications | Complex integration and compatibility issues | Flexibility to meet diverse customer requirements |

Related Posts

-

Maximizing Efficiency: How Industrial Air Compressors Transform Manufacturing Processes

-

10 Essential Tips for Choosing the Right Industrial Compressor for Your Business

-

Top 10 Air Compressor Models for Efficient Performance and Reliability in 2023

-

2025 Top Industrial Air Compressors: Key Features and Buying Guide

-

Top 10 Compressor Maintenance Tips You Can't Afford to Ignore

-

Maximizing Efficiency with Industrial Air Compressor Rental Services for Your Business Needs

Copyright © 2025

I&M Industrials Inc.

10 Akron Drive

Greenville SC 29605

Phone: 864-277-2450

GSA Number – GS07F0379Y