1-800-868-2450

My Account | Cart | Checkout

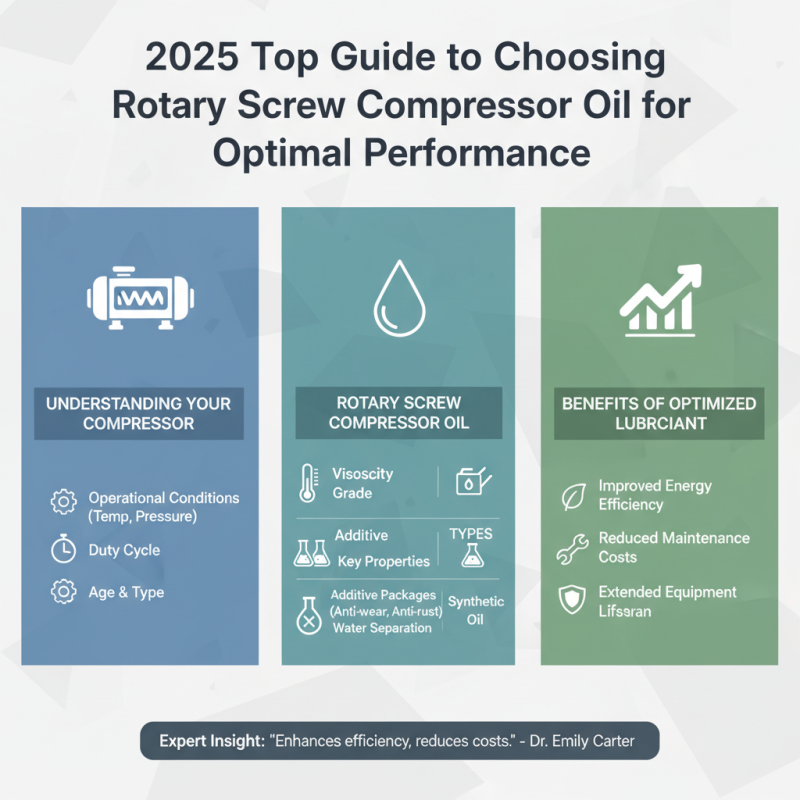

2025 Top Guide to Choosing Rotary Screw Compressor Oil for Optimal Performance

In the world of compressed air systems, the choice of the right lubricant plays a crucial role in ensuring optimal performance and longevity of rotary screw compressors. According to industry expert Dr. Emily Carter, a renowned authority on lubrication technology, "The right rotary screw compressor oil can significantly enhance efficiency while reducing maintenance costs." With so many options available in the market, understanding the unique requirements of your compressor and the specifications of the oil is essential for maximizing performance.

This guide aims to shed light on the various factors that influence the selection of rotary screw compressor oil. From understanding the viscosity grades and additive packages to considering the operational conditions of your compressor, this article will provide you with a comprehensive roadmap to make an informed decision. By optimizing the lubricant used in your rotary screw compressor, not only can you improve energy efficiency, but you also extend the lifespan of your equipment, ensuring that your operations are both cost-effective and reliable.

Understanding Rotary Screw Compressors and Their Operation

Rotary screw compressors are vital components in various industrial applications, providing a reliable source of compressed air. They operate on a simple yet efficient principle that involves the use of two interlocking helical screws to compress air. When air enters the compressor, it is captured between the screws and progressively compressed as the screws rotate. This design not only enhances efficiency but also minimizes fluctuations in output, making rotary screw compressors ideal for continuous operation in manufacturing plants, automotive facilities, and food processing industries. According to a report by the International Compressor Engineering Conference, rotary screw compressors can achieve energy efficiency rates exceeding 90% when properly maintained.

Selecting the right oil for rotary screw compressors is crucial for optimal performance. Compressor oil plays a significant role in reducing friction, enhancing cooling, and preventing wear on internal components. Quality oil helps maintain the machine's operational temperature, thereby prolonging its lifespan. It's recommended to consult manufacturer specifications, which often suggest specific oil types based on the operational environment and temperature ranges. One key tip is to regularly monitor the oil level and condition to avoid degradation and ensure consistent performance.

Additionally, consider the viscosity and additives in the oil, as they can significantly impact compressor efficiency. Synthetic oils, for example, often provide superior performance in extreme temperatures and offer better thermal stability than conventional mineral oils. Regular oil analysis can provide insights into potential issues before they escalate, helping to optimize maintenance schedules and avoid unexpected downtimes, which can otherwise cost businesses substantially in repairs and lost productivity.

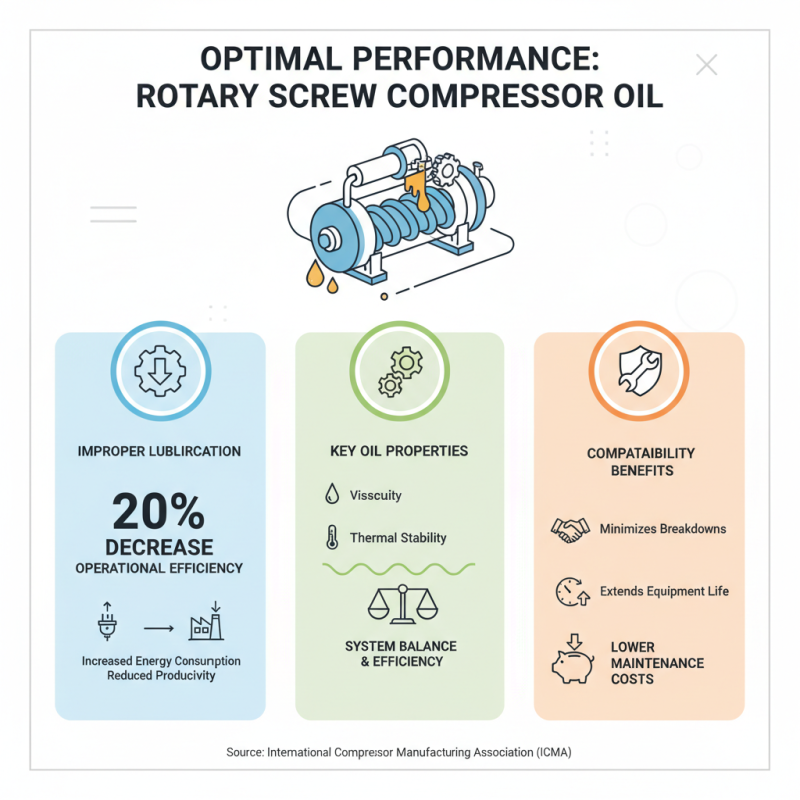

Importance of Choosing the Right Compressor Oil

Choosing the right compressor oil is crucial for ensuring the optimal performance and longevity of rotary screw compressors. According to the International Compressor Manufacturing Association (ICMA), improper lubrication can decrease operational efficiency by up to 20%, leading to increased energy consumption and reduced productivity. The oil's viscosity, thermal stability, and anti-wear properties play a significant role in maintaining balance and efficiency in these systems. Ensuring compatibility with the compressor's specific requirements not only minimizes the risk of breakdowns but also extends equipment life, ultimately resulting in lower maintenance costs.

Moreover, a report from the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) indicates that using the correct lubricant can enhance energy efficiency by as much as 15%. Quality compressor oils are formulated to withstand high temperatures and pressures, providing a protective barrier against wear and tear. This protection is vital in high-demand applications, where the operational environment can lead to rapid oil degradation. By investing in the right compressor oil, businesses can achieve significant savings in both operational costs and maintenance intervals, underscoring the importance of this critical choice in rotary screw compressor operations.

Key Characteristics of Quality Rotary Screw Compressor Oils

When selecting rotary screw compressor oil, several key characteristics are critical for ensuring optimal performance and longevity of the equipment. Quality compressor oils are formulated to provide superior lubrication properties that reduce friction and wear. According to a recent report by the International Compressors Association, oils with a high viscosity index (VI) are shown to maintain their viscosity across a wide temperature range, which is essential for the effective operation of rotary screw compressors under varying load conditions.

Another essential characteristic is thermal stability. Premium compressor oils exhibit excellent resistance to oxidation and thermal breakdown, which extends the oil’s service life, as documented in a study by the Society of Tribologists and Lubrication Engineers. These oils should also contain effective additives that prevent sludge formation and corrosion, thereby enhancing the reliability of compressor systems.

Furthermore, low foaming tendencies are vital, as excessive foam can lead to inadequate lubrication and increased wear, reducing overall efficiency. Selecting oils that meet these quality benchmarks is crucial for achieving high operational performance and minimizing costly downtime in industrial applications.

Factors Influencing Oil Selection for Optimal Performance

When selecting rotary screw compressor oil for optimal performance, several critical factors come into play. First and foremost is the viscosity of the oil, which impacts the efficiency and wear protection of the compressor. Oils with too low viscosity may not provide adequate lubrication under high temperature and pressure conditions, while oils with excessively high viscosity can lead to increased resistance and energy loss. Thus, selecting the right viscosity grade based on the operational environment and equipment specifications is paramount.

Another significant factor is the oil's thermal stability. Compressors operate under intense heat and pressure, making it essential to choose oil that can withstand these conditions without breaking down. Oils with high thermal stability maintain their performance over extended periods, reducing the need for frequent changes and ensuring that the compressor operates smoothly. Additionally, the additives present in the oil, such as anti-wear agents and oxidation inhibitors, play a vital role in enhancing performance and extending the life of both the oil and the compressor. Evaluating the compatibility of these additives with your system can significantly influence the performance outcomes.

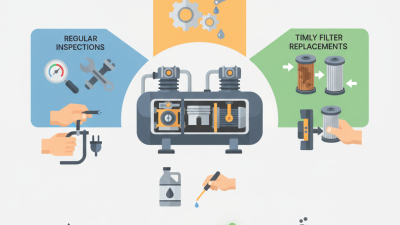

Maintenance Tips for Extending the Life of Compressor Oil

When it comes to ensuring the longevity and efficiency of rotary screw compressors, regular maintenance of compressor oil is paramount. According to the International Compressors Association, proper oil maintenance can lead to a 15-20% increase in the overall lifespan of compressor components. Maintaining optimal oil levels not only lubricates the system effectively but also helps in dissipating heat, minimizing wear and tear on the machinery.

One essential tip for extending the life of compressor oil is to adhere to the recommended oil change intervals, which are generally outlined in the compressor's operational manual. Using oil analysis programs allows operators to make informed decisions about oil replacement based on actual condition rather than pre-set schedules. The Association of Compression Technology experts recommends conducting oil analysis every 1,000 operational hours or every three months, whichever comes first. This preventative measure helps detect contaminants and degradation, ensuring that the system runs smoothly and efficiently.

Additionally, maintaining clean intake air filters plays a crucial role in prolonging oil life. Dust and particulates can enter the compressor oil through air intake, causing oxidation and rapid breakdown of the oil. The American Society of Mechanical Engineers suggests routine checks and replacements of air filters to prevent such issues and ensure the compressor operates at peak performance. Implementing these maintenance tips not only prolongs the oil life but also enhances the overall efficiency and reliability of rotary screw compressors.

2025 Guide to Rotary Screw Compressor Oil Selection

This chart illustrates the importance rating of various characteristics when selecting rotary screw compressor oil. Each characteristic is rated on a scale from 1 to 10, helping to highlight key factors that contribute to optimal compressor performance.

Related Posts

-

10 Essential Tips for Accurately Reading Your Air Compressor Gauge

-

Maximizing Efficiency with Industrial Air Compressor Rental Services for Your Business Needs

-

How to Effectively Maintain Your Air Compressor for Optimal Performance

-

Top 10 Industrial Air Solutions to Optimize Your Facility's Efficiency

-

Why Pressure Gauges are Essential for Accurate Measurements in Various Industries

-

Why Industrial Compressors are Essential for Efficient Manufacturing Processes

Copyright © 2025

I&M Industrials Inc.

10 Akron Drive

Greenville SC 29605

Phone: 864-277-2450

GSA Number – GS07F0379Y